Welding is a crucial process in constructing various structures and products. But when it comes to welding materials with different properties, things can get complicated. One of the most commonly asked questions in the welding industry is whether you can weld stainless steel to galvanized steel. To answer this question, let’s dive deep into the properties of these two metals and understand the welding process.

Stainless steel boasts exceptional durability, corrosion resistance, and strength. Meanwhile, galvanized steel is coated with a layer of zinc to prevent corrosion. Welding these two metals together can be an excellent option that combines the durability of stainless steel with the protective qualities of galvanized steel. However, this task requires extra care and attention.

To weld these materials successfully, you need special techniques and specific welding electrodes. You also need to watch out for challenges such as weld cracking and brittleness. Following proper welding procedures and safety measures is crucial for a successful weld.

In this blog post, we’ll delve deeper into this topic by discussing factors to consider, potential challenges to look out for, and tips for ensuring a successful weld. So buckle up and get ready to learn everything you need to know about welding stainless steel to galvanized steel.

What is Galvanized Steel and Stainless Steel?

Contents

Steel is a sturdy and versatile material used in various applications, ranging from construction to manufacturing. Two popular types of steel that you may have heard of are galvanized steel and stainless steel. While both have their own distinct advantages, they differ in composition and properties, making them suitable for different uses.

Galvanized steel is coated with a protective layer of zinc through a process called galvanization. This coating acts as a shield against corrosion and rust, making it a popular choice for outdoor use and in industries such as construction and automotive.

Think of it like armor that protects the steel underneath. This type of steel is more affordable than stainless steel, has good durability against outdoor elements, and is easier to weld. However, its zinc coating can produce toxic fumes during welding, which requires proper safety measures.

On the other hand, stainless steel contains at least 10.5% chromium, which gives it unique properties such as resistance to corrosion, staining, and rust.

Unlike galvanized steel, stainless steel does not require a protective coating because the chromium content provides a natural barrier against corrosion.

This makes it an ideal choice for applications where hygiene is important, such as medical equipment or food processing facilities. However, it is more expensive than galvanized steel and more difficult to weld due to its unique composition.

But what about welding these two types of steel together? It’s not without its challenges. The difference in composition between the two metals can affect the quality of the weld and the potential for corrosion in the welded area.

To overcome this challenge, specialized welding wire designed specifically for welding these metals together can be used or a technique called “electrode positive” or EP welding can be employed.

Safety Considerations When Welding Galvanized Steel to Stainless Steel

Welding galvanized steel to stainless steel is a challenging task that requires specialized knowledge and equipment. However, safety should always come first. Galvanized steel contains a layer of zinc that, when heated during welding, can release toxic fumes that pose serious health risks. To avoid these hazards, proper ventilation in the welding area is essential. You can achieve this by using exhaust fans or working in a well-ventilated area. Additionally, it’s important to wear a respirator mask specifically designed for welding fumes.

Apart from respiratory hazards, welding galvanized steel can also cause eye damage due to the bright light and intense heat produced during the process. Therefore, it is crucial to always wear appropriate eye protection such as a welding helmet with a darkened lens.

Another safety consideration when welding galvanized steel to stainless steel is the risk of fire. Zinc has a low melting point and can ignite easily, making it crucial to keep a fire extinguisher nearby and avoid using flammable materials in the welding area.

Challenges of Welding These Metals Together

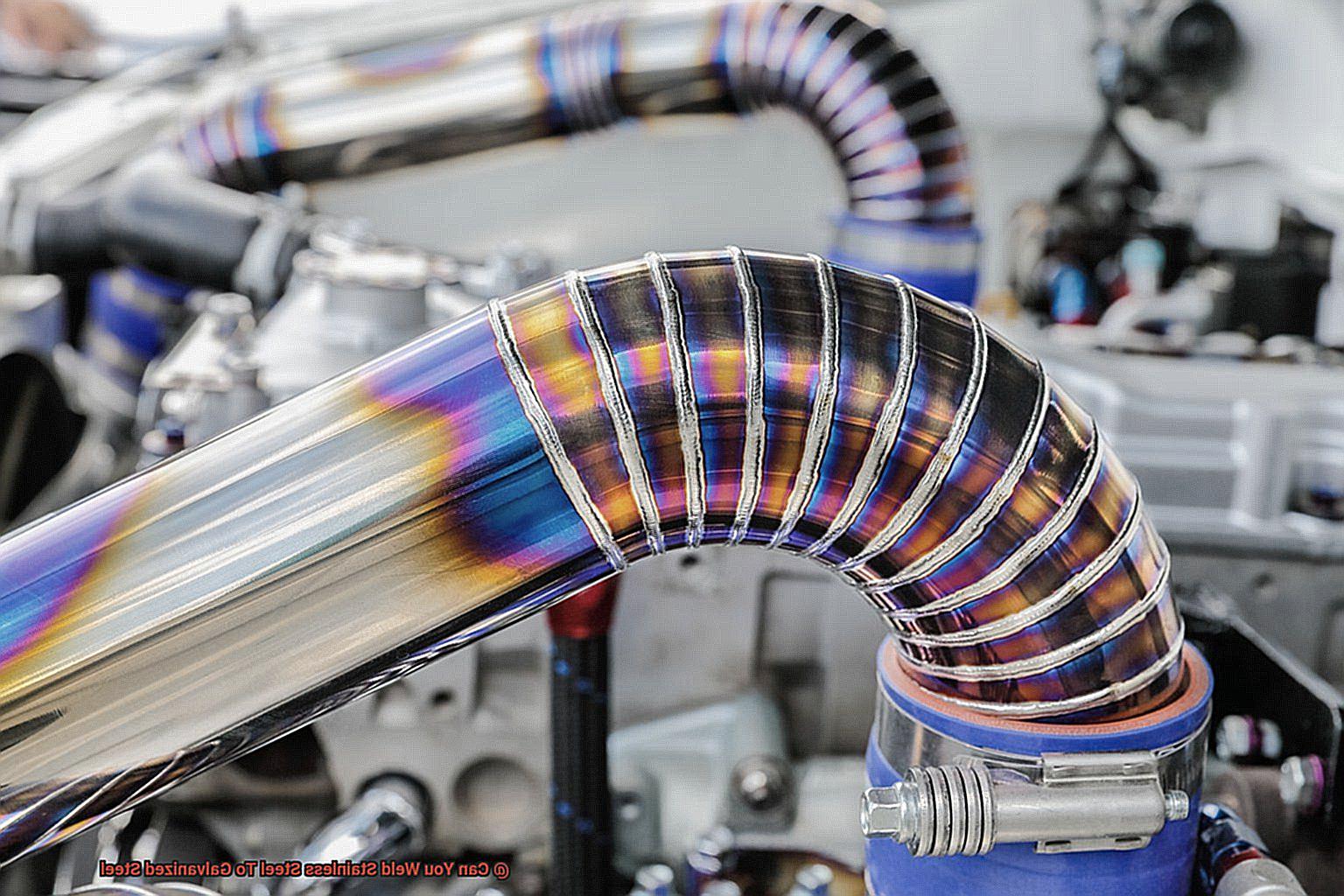

Welding stainless steel to galvanized steel can be like trying to merge two opposing forces. Experts in welding are aware of the challenges that come with this task. The main challenge faced by welders is the difference in melting points between the two metals. It’s akin to trying to bake a cake and roast a turkey at the same temperature – it’s just not possible. Galvanized steel has a lower melting point than stainless steel, which can cause distortion and warping during the welding process.

Another hurdle is the difference in chemical composition between the two metals. It’s like trying to blend oil and water – they simply don’t mix. Galvanized steel is coated with zinc to prevent rust and corrosion, while stainless steel is made up of various alloys that give it its unique properties. When welded together, the zinc coating on the galvanized steel can vaporize and mix with the stainless steel. This can weaken the weld and lead to potential porosity.

Moreover, the galvanized coating can also create an obstacle for proper fusion during welding due to its resistance to heat and its tendency to produce an oxide layer that interferes with the welding process. It’s comparable to building a sandcastle with wet sand – it just doesn’t hold together.

To address this issue, specialized welding techniques such as pulse welding or TIG welding with a high-frequency start can be utilized. This helps break through the oxide layer and improve fusion.

Specialized Welding Wire for the Job

Welding stainless steel to galvanized steel may seem like a daunting task, but with specialized welding wire, it can be done with ease. Just like baking a cake or roasting a turkey, using the right tools and techniques are essential for a successful outcome.

Choosing the right welding wire is crucial when welding these two metals together. Using welding wire specifically designed for stainless steel and galvanized steel will create the strongest weld. Flux-cored wire and dual-shielded wire are excellent options that work well with both types of metals. These wires have a flux core that protects the weld from contamination and ensures its strength and durability.

However, proper surface preparation is also essential when welding these two metals. Just like baking with dirty utensils, welding with contaminated surfaces can weaken the weld. Applying pre-weld cleaners or degreasers can help remove any dirt, oil, or other contaminants from the metal surfaces.

Electrode Positive (EP) Welding Technique

Well, listen up because this technique could be the secret ingredient to a successful weld when working with stainless steel and galvanized steel.

When EP welding, the electrode is connected to the positive terminal of the welding machine and the workpiece to the negative terminal. This creates a high-heat, low-penetration arc that allows for better control of the weld puddle. It’s like finding the perfect balance of heat and control when baking a cake – you need just the right amount to achieve perfection.

What’s even more amazing is that EP welding reduces the risk of burn-through and warping when welding dissimilar metals like stainless steel and galvanized steel. However, it’s important to note that this technique may not work for all types of stainless steel and galvanized steel combinations. Just like how different recipes require different ingredients, different types of metal require different welding techniques.

It’s always recommended to consult with a professional welder or engineer before attempting to weld these materials together.

Safety precautions should also be followed, such as wearing protective gear and ensuring proper ventilation in the work area.

Just like how you wouldn’t start baking a cake without proper safety measures, welding should always be done safely.

Preparing the Metals Before Welding

Creating a masterpiece of welding is no small feat, and it all starts with the crucial step of preparing the metals before welding. This step is especially critical when working with dissimilar metals such as stainless steel and galvanized steel because they have different chemical compositions that require careful preparation to ensure a strong bond.

Cleaning the metals is the first vital step in preparing them for welding. Just as a painter would clean their canvas before painting, welders must also clean the metal surfaces to guarantee a robust weld.

Dirt, oil, or grease on the surface of the metal can interfere with the welding process and weaken the weld. Therefore, using a wire brush or sandpaper to remove any surface contaminants is crucial.

Once the metals are clean, it’s time to tackle the next step: removing any galvanized coating from the surface of the galvanized steel. Galvanized steel is coated with a layer of zinc, which can create problems when welding. The zinc coating produces a toxic gas when heated, which can be harmful to the welder and weaken the weld. Welders may use either a chemical solution or grind off this coating to eliminate this risk.

After removing the galvanized coating, it’s essential to protect both metals from further corrosion. Stainless steel is resistant to corrosion, but galvanized steel is not. This means that without proper protection, galvanized steel will begin to corrode after welding.

To prevent this from happening, apply a corrosion inhibitor to both metals before welding. This creates a barrier between the metal and oxygen, preventing oxidation and corrosion.

GwRhUa4th2c” >

Conclusion

To sum up, welding stainless steel to galvanized steel is possible but requires specialized knowledge, techniques, and equipment. Both metals have their own unique advantages that make them suitable for different applications.

Galvanized steel is more affordable than stainless steel and has good durability against outdoor elements, while stainless steel offers superior corrosion resistance and strength. However, welding these metals together can present challenges such as differences in melting points and chemical composition that can affect the quality of the weld and potential for corrosion.

To tackle these challenges head-on, specialized welding wire designed specifically for welding these metals together can be used or a technique called “electrode positive” or EP welding can be employed. It’s important to take proper safety measures due to the toxic fumes released during welding galvanized steel.

Preparing the metals before welding is crucial in ensuring a strong and reliable weld. Welders must thoroughly clean both surfaces, remove any galvanized coatings from the surface of the galvanized steel, and protect both metals from further corrosion by applying a corrosion inhibitor.