As a homeowner, you know that your plumbing system is one of the most critical components of your home. It’s essential to ensure that everything is in good condition to avoid any costly repairs or inconvenience down the line. One of the key elements of your plumbing system is solder, a metal alloy used to connect and seal pipes and fittings together.

While plumbing solder may seem like a straightforward material, it’s crucial to make sure it’s correctly installed and maintained to prevent leaks, blockages, and other plumbing issues. But have you ever wondered if plumbing solder can go bad or expire? The answer is yes, and in this post, we’ll explore why.

Solder that has gone bad can cause significant problems for your plumbing system. From leaks to blockages, the consequences can be costly and frustrating. That’s why it’s crucial to understand what causes plumbing solder to go bad so that you can prevent it from happening.

In this blog post, we’ll take an in-depth look at the reasons why plumbing solder can go bad. We’ll cover everything from exposure to heat and moisture to poor installation techniques. By understanding these factors, you’ll be better equipped to ensure that your plumbing system is properly sealed and functioning at its best.

So get ready to explore the world of plumbing solder with us. We’ll show you how to recognize the signs of bad solder and what steps you can take to prevent it from causing problems in your home. With our help, you’ll be able to keep your plumbing system in top condition for years to come.

What is Plumbing Solder?

Contents

The answer lies in plumbing solder – a metal alloy made up of lead, tin, and other metals that is used to join pipes and fittings together in plumbing systems.

Since ancient times, people have been melting metal alloys to create a strong and durable bond between two objects. Today, plumbing solder is still widely used in residential and commercial plumbing systems around the world. It comes in the form of wire or sticks that are melted with a torch or soldering iron to create a permanent bond between two pieces of pipe.

Plumbing solder is an essential component of any plumbing system as it creates a secure and leak-proof joint that ensures pipes function correctly. Without it, pipes would be prone to leaks and could potentially cause serious damage to homes or buildings.

The process of using plumbing solder involves heating the wire or stick with a torch or soldering iron and applying it to the joint between two pieces of pipe. As it cools and hardens, it forms a permanent bond between the two pieces of pipe.

It’s important to note that like any material, plumbing solder can deteriorate over time due to factors like corrosion, improper installation, or extreme temperatures. Regular maintenance and inspection of the plumbing system are crucial to identifying potential problems before they become major issues.

In conclusion, plumbing solder is an important tool for plumbers and DIY enthusiasts alike. It ensures that plumbing systems are safe, functional, and long-lasting.

Factors That Can Cause Plumbing Solder to Go Bad

Corrosion

When metal is exposed to moisture and oxygen, it can cause plumbing solder to weaken, which can eventually lead to leaks in your pipes. But fear not, as an expert in plumbing, I’m here to share some insights on how you can prevent this from happening.

One of the most common causes of corrosion in plumbing solder is the use of low-quality solder or impurities in the water supply. Over time, exposure to moisture can break down the solder causing leaks that can be challenging to detect until they have caused significant damage. Additionally, some water supplies contain corrosive chemicals and minerals that can corrode pipes and weaken solder joints.

To avoid such a nightmare, it’s essential to use high-quality plumbing solder that is designed for use with your specific pipes and fittings. Equally important is ensuring that your pipes are adequately installed and maintained to prevent moisture from accumulating and causing damage.

Regular inspections of your plumbing system are also recommended as they can help you identify any signs of corrosion before they become a major issue. Addressing any leaks or signs of corrosion immediately is vital in preventing further damage.

In summary, using high-quality materials, proper installation, and maintenance are critical steps in preventing corrosion in plumbing solder. Taking these measures will help ensure that your plumbing system remains strong and reliable for years to come.

Improper Installation

When it comes to plumbing, improper installation can be a recipe for disaster. One of the most common reasons plumbing solder can go bad is when it’s not applied correctly or if there are defects in the installation process. Leaks and other issues can arise, leading to costly repairs and water damage in your home.

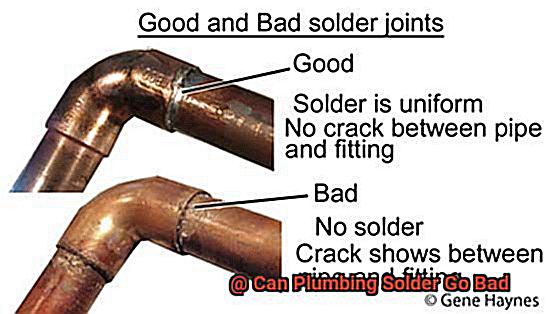

Pipes that aren’t cleaned properly before applying the solder can lead to dirt and debris mixing with the solder, weakening its integrity over time. This breakdown in the solder can cause leaks and other problems that could have been avoided with proper installation techniques.

Using the wrong type of solder for your specific plumbing needs can also cause corrosion and other damage over time. Different types of solder are available for various plumbing applications, so it’s crucial to use the right one for your specific needs.

Heating the solder to the correct temperature during installation is also essential. If the solder isn’t heated enough, it may not bond correctly with the pipes and fittings, leading to leaks and other issues. Overheating the solder can cause damage to the pipes and fittings themselves.

To ensure your plumbing system remains leak-free and in good condition for years to come, proper installation is critical. Carefully follow all manufacturer instructions, clean all pipes and fittings thoroughly before applying the solder, and use the correct type of solder for your specific plumbing needs.

Extreme Temperatures

Whether it’s blazing hot or freezing cold, it’s essential to use the right type of solder and installation techniques to prevent any potential disasters.

When exposed to high temperatures, plumbing solder can melt and weaken, leading to leaks in your system. Similarly, freezing temperatures can cause pipes to expand and potentially crack or break the soldered joints. That’s why it’s crucial to use the appropriate type of solder for your specific needs, such as silver solder which is designed to withstand high temperatures.

However, using the right type of solder is just the first step. It’s also essential to ensure that the joints are properly cleaned and prepared before soldering. Too much or too little solder can also weaken over time and eventually fail. That’s why a quality soldering job is essential.

To prevent any potential damage from extreme temperatures, regular maintenance and inspections of your plumbing system are key. This will help identify any potential issues before they become major problems. By taking these precautions, you can avoid costly repairs and water damage in your home.

Maintenance and Inspection

Taking care of your plumbing system is crucial to prevent costly repairs or damage to your property. One crucial aspect to consider when it comes to maintenance and inspection is the solder used in the connections. Solder is a metal alloy melted and used to join two pieces of metal, commonly copper pipes in plumbing systems.

Unfortunately, solder can degrade or corrode over time, leading to leaks in the plumbing system. This can happen due to a variety of factors such as exposure to chemicals, high heat, or regular wear and tear. That’s why it’s essential to inspect soldered connections regularly for any signs of degradation or leaks.

One common indication that solder may be going bad is discoloration. If you notice that your solder has turned green or black, it could indicate corrosion or oxidation. Additionally, visible cracks or gaps in the soldered connection could also be signs of degradation.

Regular maintenance and inspection can help prevent these issues from occurring. Detecting potential problems early on is crucial to avoid further damage or costly repairs. Neglecting these problems could lead to severe consequences, including water damage and mold growth.

While plumbing solder does not necessarily “go bad” in the traditional sense, it can degrade over time and lead to leaks in the plumbing system. Regular maintenance and inspection can help prevent these issues and ensure the longevity of your plumbing system.

8IV7oG43DZ0″ >

Conclusion

To sum up, plumbing solder is a crucial element of any plumbing system, as it creates secure and leak-proof joints that keep pipes functioning correctly. However, it’s important to note that plumbing solder can go bad or expire over time due to various factors such as moisture exposure, high temperatures, improper installation techniques, and corrosion.

Regular maintenance and inspection of your plumbing system are essential in identifying potential problems before they become major issues. Using high-quality plumbing solder specifically designed for your pipes and fittings is equally important. Proper installation and maintenance of your pipes prevent moisture buildup that can cause damage.

By taking proactive steps to prevent these factors from causing damage, you can ensure that your plumbing system remains strong and reliable for years to come. Remember, prevention is always better than cure. Regularly inspecting your soldered connections for signs of degradation or leaks is crucial to avoid further damage or costly repairs. Ignoring these issues could lead to severe consequences like water damage or mold growth.

In short, understanding the factors that can cause plumbing solder to go bad is critical in keeping your home safe from expensive repairs or inconvenience down the line.