Are you tired of relying solely on soldering to join materials together?

Soldering is a popular technique in electronics, plumbing, and jewelry-making, but it’s not always feasible. Maybe you don’t have access to a soldering iron or the materials you need to join are incompatible with solder.

Whatever the reason may be, fear not. There are numerous alternatives available that are both cost-effective and easy-to-find in most households.

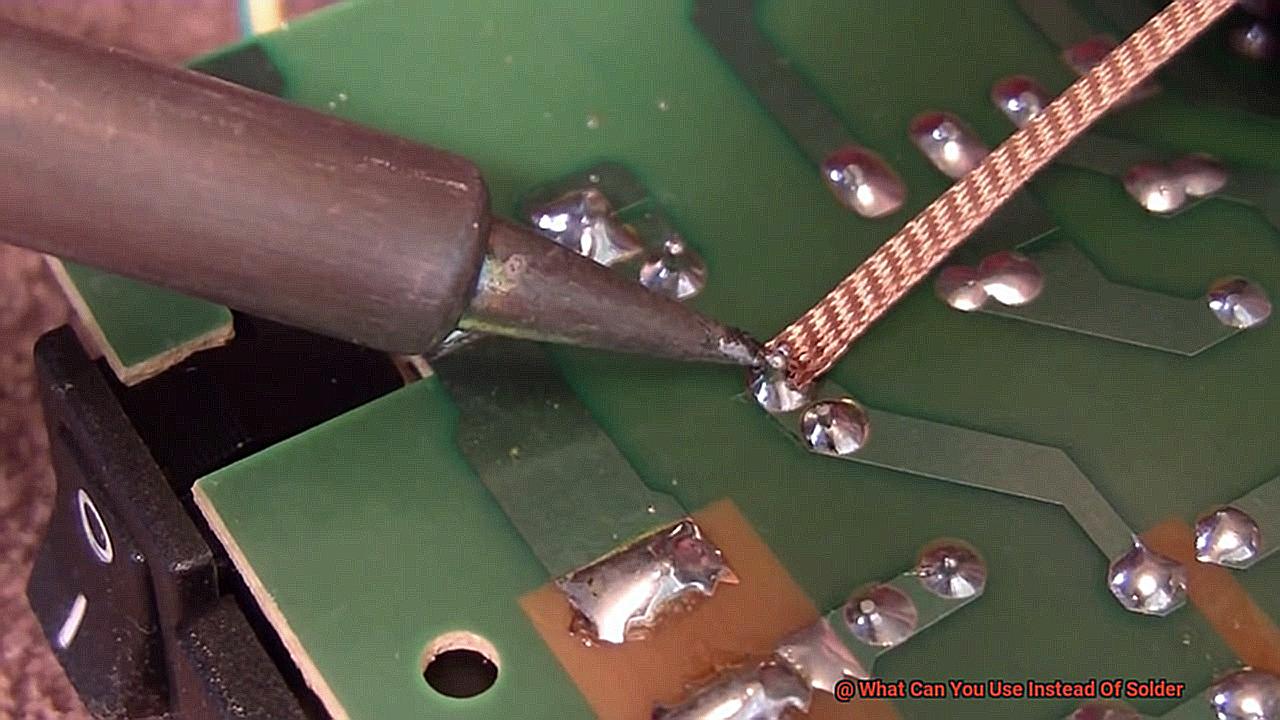

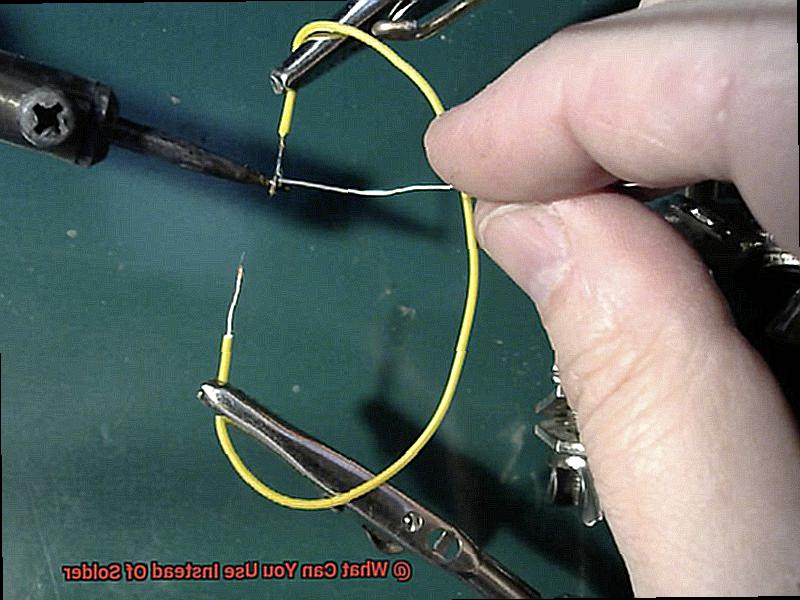

One alternative is conductive glue – an adhesive that has conductive properties and can be used to connect electrical circuits without the need for soldering. Wire wrapping is another option that involves tightly wrapping one wire or component around another wire without using any solder.

If you’re working with metal components, crimping may be your best bet – this technique involves bending and compressing metal using a tool to create a secure joint. Finally, heat shrink tubing is another great alternative – by covering the joint with a plastic tube that contracts when heated, it forms a tight seal.

In this blog post, we’ll delve into each of these alternatives in more detail and explain how they can be effectively used for your next DIY project or repair job. So next time you find yourself struggling with soldering, remember that there are other options available to you.

Don’t let lack of equipment or incompatible materials hold you back from creating something amazing.

Brazing: A Stronger Bond with Higher Temperatures

Contents

- 1 Brazing: A Stronger Bond with Higher Temperatures

- 2 Welding: Advanced Skills and Equipment for Permanent Joints

- 3 Adhesives: Epoxy and Super Glue for Metal Bonding

- 4 Mechanical Fasteners: Screws, Bolts, and Rivets for Heat-Sensitive Situations

- 5 Considerations for Choosing an Alternative to Solder

- 6 Pros and Cons of Alternatives to Solder

- 7 Conclusion

This process involves heating the metals being joined to temperatures between 800-1900°F and using a filler metal, known as brazing alloy, to create a sturdy bond. Brazing offers several benefits over soldering, including the ability to join a wider range of metals such as steel, copper, and brass.

It also produces more durable bonds due to the higher temperatures involved. While it may require more skill and equipment than soldering, the end result is often worth the effort.

When choosing a brazing alloy, consider factors such as melting temperature, strength, and compatibility with the metals being joined. Silver-based alloys are a popular choice for brazing due to their high strength and compatibility with various metals.

Torch brazing involves using a torch to heat the metal and filler metal while furnace brazing involves placing the joint in a furnace and heating it to the required temperature.

Welding: Advanced Skills and Equipment for Permanent Joints

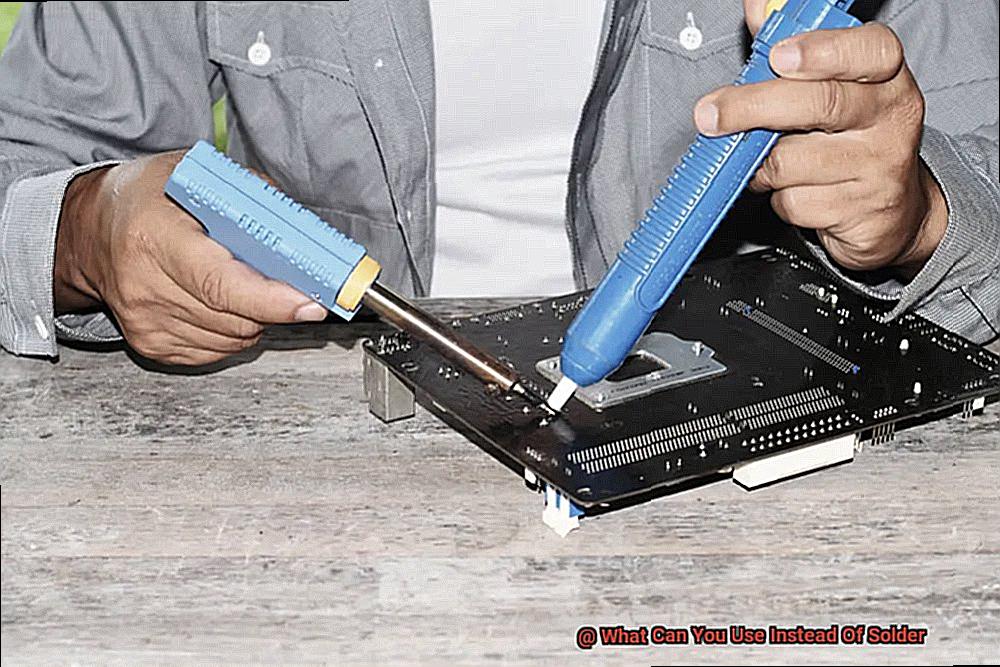

When it comes to creating permanent metal joints, soldering may not always cut it.

This is where welding and brazing come in as reliable alternatives, but don’t be fooled, these processes require advanced skills and equipment that can be costly and time-consuming to acquire. Welding involves melting and fusing metal pieces together using heat and pressure.

With different welding processes available such as MIG, TIG, and stick welding, each has its own set of advantages and disadvantages. For example, MIG welding is a breeze to learn and can be used on various metals such as steel, aluminum, and stainless steel.

Meanwhile, TIG welding is ideal for precision work on thinner metals. Meanwhile, brazing is another alternative to soldering that involves heating two metal pieces until they are hot enough to melt a filler metal that is then drawn into the joint by capillary action.

The filler metal typically has a lower melting point than the two pieces being joined, allowing it to fill the gap between them without melting them. It’s important to note that both welding and brazing require advanced skills and equipment.

Therefore, before choosing either option, it’s essential to consider the specific needs of your project. Welding equipment can be costly but necessary for creating strong bonds between metals.

On the other hand, brazing equipment is less expensive but requires more skill in controlling the temperature of the metal pieces. In summary, welding and brazing are both effective alternatives to soldering for creating permanent joints in metalwork.

Adhesives: Epoxy and Super Glue for Metal Bonding

Epoxy is a two-part adhesive that consists of a resin and hardener.

Once mixed, it forms a robust bond that can withstand high impact and stress.

Epoxy is ideal for uneven or rough metal surfaces as it can fill in gaps, creating a smooth and even surface. It’s also perfect for bonding metal to other materials like wood or plastic.

If you’re looking for an almost instant bond between metal surfaces, super glue or cyanoacrylate adhesive is a great option. It’s perfect for small and delicate applications.

However, it may not be suitable for high-stress situations because it can become brittle over time. To ensure the best result when using adhesives for metal bonding, follow the manufacturer’s instructions carefully.

Make sure to clean the surfaces thoroughly, removing any dirt, grease, or oil before applying the adhesive evenly. Allow sufficient time for it to cure before applying any stress or load on the bond.

While adhesives like epoxy and super glue may not be as strong as solder, they are still effective alternatives for many metal bonding applications.

Mechanical Fasteners: Screws, Bolts, and Rivets for Heat-Sensitive Situations

These fasteners, such as screws, bolts, and rivets, offer an excellent alternative to soldering by mechanically joining two or more pieces of metal without the need for heat. The beauty of using mechanical fasteners is that they provide a strong and secure bond without the risk of damaging heat-sensitive components.

They are versatile and can be used in a wide range of applications, from electronics to construction. So let’s take a closer look at each type of mechanical fastener.

Screws are probably the most commonly used mechanical fasteners out there. They come in various sizes and shapes, each with its unique features that make them suitable for specific applications.

For example, self-tapping screws have a pointed end that makes it easier to start threading into the material without the need for a pilot hole. This saves time and effort when you’re in a hurry.

Bolts are similar to screws but typically have a larger diameter and require a nut to hold them in place. Bolts come in different grades and strengths, allowing them to be used in applications that require high levels of tension or shear strength.

Plus, they’re pretty effective for heavy-duty jobs like construction. Lastly, rivets are another type of mechanical fastener that can be used as an alternative to soldering.

Rivets create a permanent bond by deforming the metal around the shank of the rivet. This bond is resistant to vibration and shock, making it ideal for applications where stability is crucial.

So, mechanical fasteners such as screws, bolts, and rivets are excellent alternatives to soldering in heat-sensitive situations. They provide a strong and secure bond without the need for heat, making them ideal for use in electronic devices or other heat-sensitive applications.

Considerations for Choosing an Alternative to Solder

Different projects require varying levels of strength and durability, making it crucial to choose an alternative that meets those requirements. For instance, in construction projects, mechanical fasteners like screws, bolts, and rivets may be more suitable than adhesives.

The materials you’ll be working with also play a vital role in selecting a viable alternative. Some alternatives may not be compatible with certain materials or may require additional preparation to be effective.

Thus, researching and testing potential alternatives beforehand is essential. Cost is another important consideration, but it’s vital to weigh the cost savings against the potential risks and drawbacks.

While some alternatives may be cheaper than solder, they may not provide the same level of strength or reliability. Ease of use is another factor to keep in mind while selecting an alternative.

Some alternatives may require specialized equipment or training, while others may be more user-friendly. It’s essential to choose an option that you feel comfortable working with and can help you achieve your desired results.

Lastly, environmental impact should also be considered while selecting an alternative to solder as some options may contain harmful chemicals or produce toxic fumes that can harm both your health and the environment.

Pros and Cons of Alternatives to Solder

It’s essential to weigh the pros and cons of each alternative before making a decision. First on the list is mechanical fasteners.

This method involves using screws, bolts, or nuts to hold two pieces of metal together. The advantage of using mechanical fasteners is that it’s easy to use and doesn’t require any specialized skills.

However, the disadvantage is that it can be time-consuming and may require drilling holes in the metal. Another alternative is adhesives like epoxy, cyanoacrylate, and acrylics.

Adhesives are easy to use and don’t require any specialized skills. They also don’t require any heat, which makes them ideal for delicate electronic components.

But adhesives may not be as strong as solder and may not hold up well under high temperatures. Brazing is another option where a filler metal that melts at a higher temperature than solder is used to join two pieces of metal together.

Brazing creates a stronger joint than solder and can withstand higher temperatures, but it requires specialized skills and equipment. Last but not least, welding involves melting two pieces of metal together using heat.

Welding creates a very strong joint that can withstand high temperatures and pressure. However, it requires specialized equipment and skills.

When considering alternatives to solder, it’s essential to weigh the pros and cons of each option before making a decision. Mechanical fasteners are easy to use but can be time-consuming, while adhesives may not be as strong as solder but are ideal for delicate components.

Brazing creates a stronger joint than solder but requires specialized skills, and welding creates a very strong joint but also requires specialized equipment and skills. Ultimately, the best alternative to solder will depend on the specific application and the materials being used.

Conclusion

In conclusion, soldering is a widely used technique for joining materials, but it’s not always the most practical option.

Luckily, there are plenty of alternatives that are both cost-effective and readily available in most households. Conductive glue is an excellent alternative for those looking for a quick fix.

Wire wrapping and crimping are ideal if you’re working with delicate electronics or wires. Heat shrink tubing can also provide a secure bond without the need for solder.

Brazing is a fantastic option if you’re working with metals like steel, copper, or brass. It produces stronger bonds than solder due to the higher temperatures involved.

However, welding requires advanced skills and equipment that can be expensive and time-consuming to acquire. Adhesives like epoxy and super glue may not be as durable as solder, but they are still effective alternatives for many metal bonding applications.

Mechanical fasteners such as screws, bolts, and rivets provide a robust and secure bond without the need for heat.

When selecting an alternative to soldering, it’s crucial to consider several factors such as the project you’re working on, materials being used, cost savings against potential risks and drawbacks, ease of use and environmental impact.