Are you a DIY enthusiast, hobbyist, or professional metalworker looking to solder brass to brass?

If so, you may be wondering if it’s possible. The answer is yes, but with a few important caveats.

Brass is an alloy made by combining copper and zinc. Its properties can vary depending on the ratio of these two elements.

Therefore, soldering brass to brass requires attention to detail. The most common type of solder used for brass is silver-based.

However, it has a higher melting point than other solders and requires an acid or flux to bond properly. Without these precautions, the solder can become brittle or leak.

To successfully solder brass to brass, you’ll need patience and careful application of heat. It’s also crucial to thoroughly clean the surfaces beforehand.

By reading on, you’ll learn how to achieve a successful result in your next project.

What is Soldering?

Contents

Soldering is a magical process that can turn two metal pieces into a unified whole.

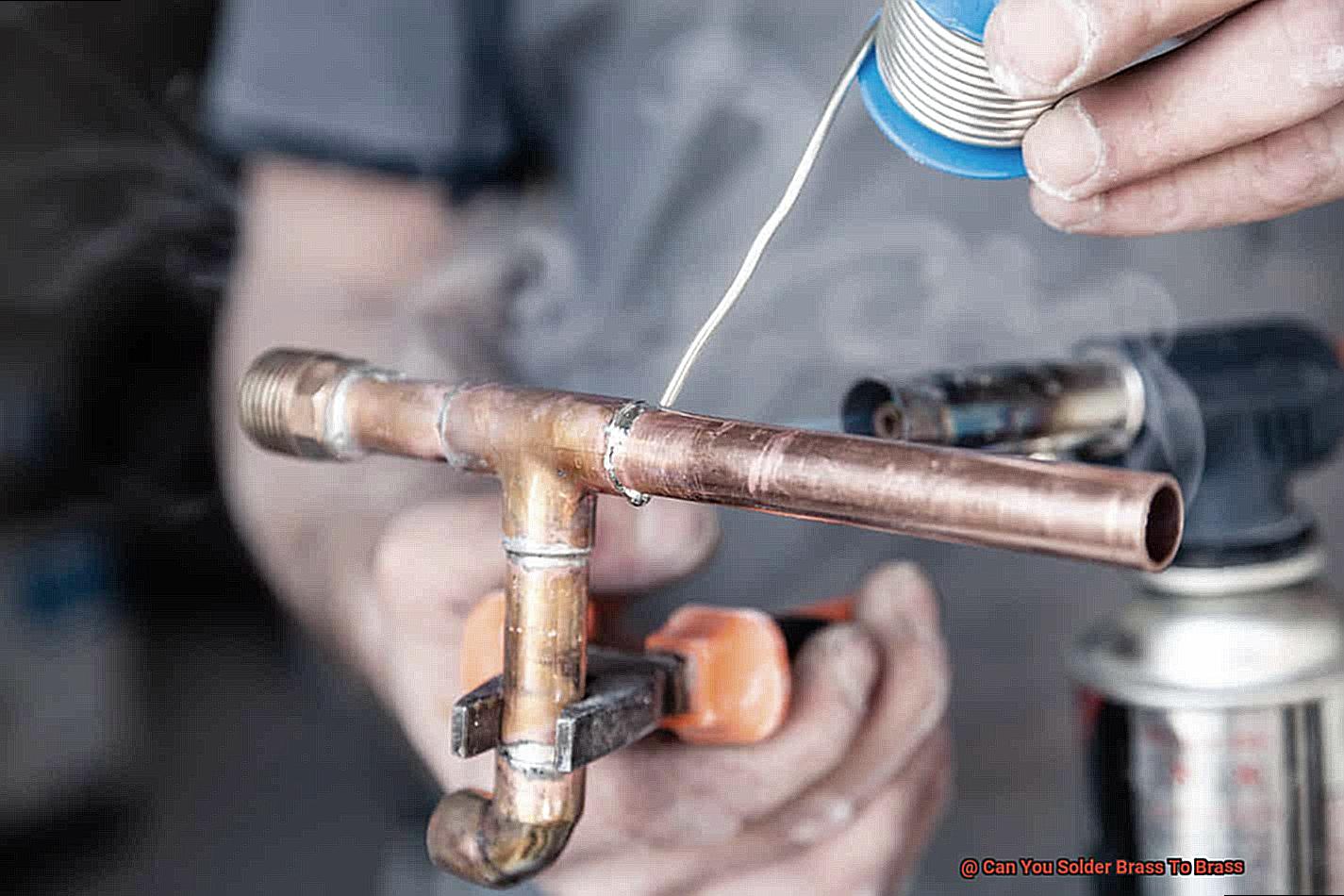

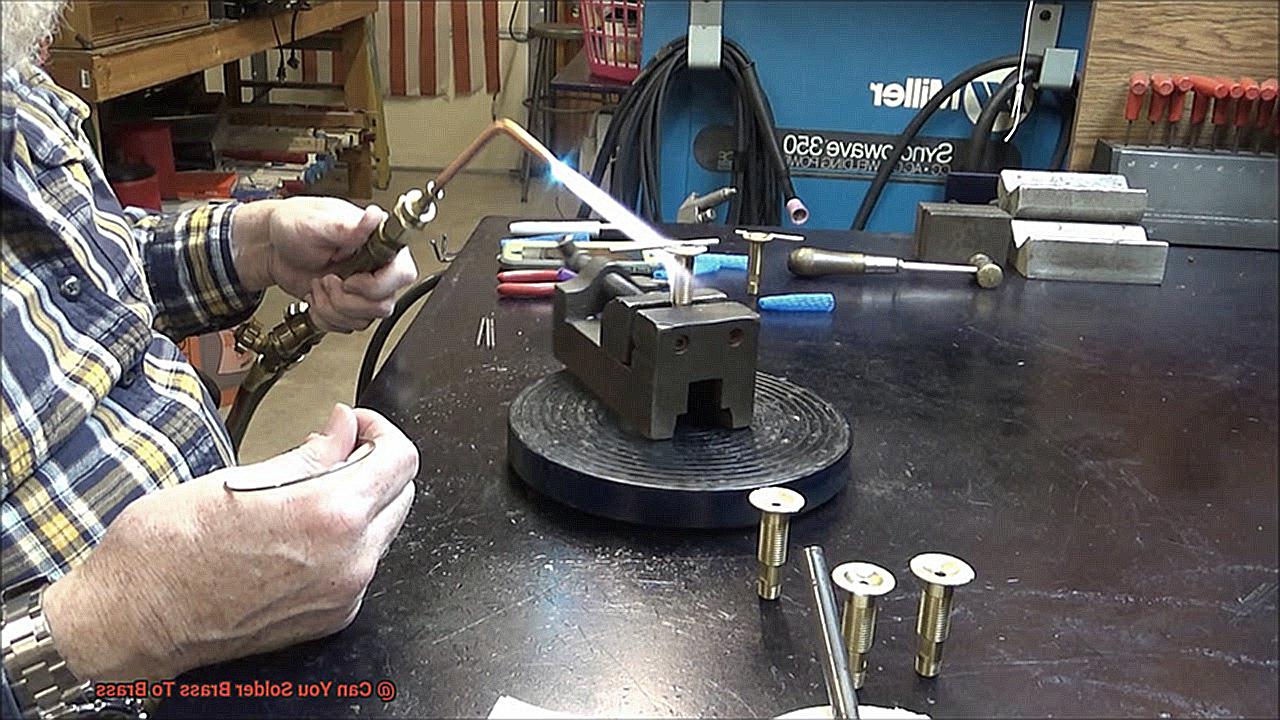

Whether you’re tinkering with electronics, fixing plumbing, or creating beautiful jewelry, soldering is an essential skill to have in your repertoire. To get started, you’ll need some basic tools, including a soldering iron or torch, flux, solder wire or rod, and a cleaning agent.

These trusty sidekicks will be with you every step of the way. One of the most crucial steps in soldering is cleaning the surfaces thoroughly.

Metal can form an oxide layer when exposed to air, which can hinder adhesion. For instance, brass can be especially finicky to work with because of this layer.

Using sandpaper, wire brushes, or even soaking in vinegar or lemon juice are all ways to clean the surface thoroughly. Once clean, applying a flux is like having a superhero by your side.

The flux helps remove any remaining oxide layer and promotes the flow of the solder. There are many types of flux available, from rosin-based to water-soluble.

Use a brush or cotton swab to apply a thin layer to the joint area. When the joint area is hot enough (thanks to your trusty propane torch or soldering iron), it’s time to add the solder.

Remember that less is more. Applying too much solder or overheating the metal can weaken the joint.

So take your time and aim for a small amount of solder on one side of the joint that will flow into the other side by capillary action. After cooling down, use a damp cloth to clean any remaining flux residue.

Your resulting joint should be strong and durable if you followed proper soldering techniques. In conclusion, soldering is an essential skill for anyone working with metals.

By using suitable solder alloys, cleaning surfaces properly, applying flux effectively, and heating the material correctly, you can create strong bonds between two metal pieces.

Can You Solder Brass To Brass?

It’s a common task for welders, jewelers, and metalworkers, and with the right materials and techniques, you can create a strong and durable bond that will last a lifetime.

First: can you solder brass to brass? Yes, you can.

Brass is a popular alloy made from copper and zinc, and it’s versatile and perfect for various applications. The key to successful brass-to-brass soldering is using the right type of solder and flux.

When it comes to soldering, there are different types of solder available in the market. But for brass-to-brass soldering, brass-based solder is your best bet.

Why? Because it has a similar composition to the base material, which creates a strong bond and ensures durability.

But here’s the kicker: using the right type of flux is just as important. Flux is like your trusty sidekick that helps remove oxidation and other impurities from the metal surface and allows the solder to flow evenly.

For brass-to-brass soldering, an acid-based flux is recommended as it dissolves any oxide layers on the surface and ensures a clean joint. Now that we’ve got our materials sorted out, let’s talk technique.

Before starting the soldering process, it’s crucial to prepare the surfaces by cleaning them thoroughly with sandpaper or steel wool. This will remove any dirt or debris that can interfere with the bonding process.

Next up, we apply the flux on both pieces using a brush or applicator. Then, we place the two pieces together and apply heat using a torch or soldering iron until the solder melts and fills the gap between them.

The trick here is to be careful while heating the brass as it can easily melt or warp if exposed to excessive heat. Use low heat and work slowly around the joint until the solder melts completely.

What Are the Challenges of Soldering Brass to Brass?

Soldering brass to brass might seem like an easy task, but it can be more complicated than anticipated.

As a knowledgeable expert in this field, I’m here to explain the challenges that you might encounter and offer tips on how to overcome them. One of the main challenges when soldering brass to brass is the melting point of the metal.

Brass has a lower melting point compared to other metals, which means that it’s crucial to use a high-quality soldering iron or torch that delivers precise and consistent heat. Overheating brass can lead to melting and weakened joints, so it’s important to be mindful of this.

Another challenge is surface contamination. Brass is susceptible to oxidation and other forms of contamination, so cleaning the surfaces thoroughly before soldering and using a flux specifically designed for brass are crucial steps.

This ensures that the solder adheres properly and creates a strong bond. Lastly, ensuring that the joint is strong enough to withstand use over time is critical.

This requires careful attention to detail when preparing the surfaces, applying the solder, and ensuring that the joint is properly cooled and solidified before use. A weak joint can cause problems later on and may require redoing the entire process.

What Solder Alloy Should Be Used to Join Two Pieces of Brass?

When it comes to soldering brass to brass, the type of solder alloy used is crucial. Think of it like a puzzle – you need the right pieces to fit together perfectly.

The most commonly used solder alloys for brass are those that contain a high percentage of copper, such as brass or bronze alloys. These alloys have a lower melting point than the brass being joined, which allows them to flow and bond the two pieces together seamlessly.

So, what’s the best option? One popular choice is a brass alloy solder such as 65/35 or 60/40.

These alloys contain 65% or 60% copper, respectively, and are often combined with zinc and other metals to create a strong bond. Another option is bronze alloy solder, which contains a mixture of copper, tin, and other metals.

It’s crucial to use a solder alloy with a lower melting point than the brass being joined. Using an alloy with a higher melting point can cause issues such as incomplete bonding or damage to the brass pieces.

It’s like trying to force a square peg into a round hole – it just won’t work. Instead, choose an alloy that has a lower melting point than the brass being joined to ensure that it flows and bonds properly.

Another important consideration is compatibility. Some solder alloys may react poorly and weaken the joint over time if they are not compatible with the brass being joined.

It’s like mixing oil and water – they just don’t mix well. Therefore, make sure to choose an alloy that is compatible with the brass being joined to ensure a strong and lasting bond.

A brass or bronze alloy solder with a lower melting point than the brass being joined is typically the best choice for achieving this.

How To Prepare The Surface for Soldering?

Soldering brass to brass can be a challenging task, but with the right preparation, it can be a breeze. One of the most critical steps in the process is preparing the surface for soldering.

Here are some steps to follow to ensure a successful bond between two pieces of brass:

Thoroughly Clean the Brass

It’s crucial to remove any contaminants such as dirt, grime, or oxidation that may be present on the brass surface. A mixture of vinegar and salt or a commercial brass cleaner can do the trick.

Create a Rough Surface

To create a bond that will last, you need to roughen up the surface slightly. Use fine grit sandpaper or steel wool to create a slightly rough texture that will help the solder adhere better.

Ensure Perfect Fit

It’s essential to make sure that the two pieces of brass fit together perfectly. Any gaps or unevenness in the joint can prevent the solder from creating a strong bond. File down any rough edges or use pliers to bend the pieces into shape before beginning the soldering process.

Apply Flux

Flux is an essential component of the soldering process as it helps remove any oxides from the surface of the brass and prevents new ones from forming. It also helps the solder to flow more easily and creates a stronger bond. Use only enough flux to cover the surfaces without leaving any excess.

Heat Up and Solder

Use a propane torch or soldering iron until it reaches the temperature required for your chosen solder alloy. Once hot enough, apply a small amount of solder to one side of the joint and let it flow into the other side by capillary action.

After completing these steps, clean up any remaining flux residue from the joint area once it cools down. By following these steps, you can create a strong bond between two pieces of brass that will last for years to come.

In conclusion, preparing the surface for soldering brass to brass is a crucial step in ensuring a successful bond. By cleaning and roughening up the surfaces, applying flux, and heating up and soldering the joint area, you can create a strong and long-lasting bond.

How To Successfully Solder Brass to Brass?

Don’t worry, it’s not as difficult as it may seem. With a few simple steps, you can create a strong bond between two pieces of brass that will stand the test of time.

Choose the Right Solder

The first step to successfully soldering brass to brass is selecting the right type of solder. Silver-based solder is recommended because it has a lower melting point than brass and won’t damage the material. This type of solder is easy to work with and creates a strong bond.

Clean the Surfaces

Before beginning the soldering process, it’s crucial to clean the surfaces of both brass pieces. Any dirt, grease, or oxidation can prevent the solder from adhering properly. A wire brush or sandpaper can be used to remove any unwanted residue from the surface.

Apply Flux

Flux is an essential component in the soldering process. It helps remove any remaining oxidation and promotes the flow of solder between the two pieces of brass. Make sure to apply flux evenly to the joint area.

Heat Up the Joint Area

Now it’s time to heat up the joint area using a torch or soldering iron. Be sure to do so slowly and evenly to prevent warping or damage to the material. Once the brass has reached the correct temperature, apply the silver-based solder to the joint area.

Clean Off Any Excess Residue

After the solder has cooled and solidified, it’s important to clean off any remaining flux residue from the joint area using a wire brush and water. This will help prevent corrosion or other damage from occurring over time.

So, successfully soldering brass to brass requires patience, attention to detail, and the right tools and materials. However, with these factors in place, it’s possible to create a strong and long-lasting bond between two pieces of brass.

kaEGDWzqP3o” >

Conclusion

In conclusion, it is possible to solder brass to brass with the right materials and techniques.

Brass, an alloy made from copper and zinc, can be challenging to work with due to its susceptibility to oxidation and contamination. Therefore, it is crucial to clean the surfaces thoroughly before soldering and use a flux specifically designed for brass.

Selecting the proper type of solder alloy is also vital for creating a robust bond. Typically, brass or bronze alloys with a lower melting point than the brass being joined are the best choice for achieving this.

To successfully solder brass to brass, you must exercise patience and carefully apply heat. It is essential to heat up the joint area slowly and evenly using a torch or soldering iron as overheating can cause melting and weakened joints.

Overall, by following proper soldering techniques such as cleaning surfaces effectively, applying flux correctly, and heating the material appropriately, you can create strong bonds between two pieces of brass that will last for years.