Welding stainless steel is a skill that requires some expertise, but it’s an essential one for any welder looking to expand their capabilities.

MIG welding is a popular method used by many welders because of its strength and ease of use when welding stainless steel. However, welding stainless steel comes with specific considerations, including the use of proper welding wire.

But what if you don’t have access to the right type of wire? Can you use normal MIG wire for welding stainless steel?

This question often pops up among welders because let’s face it; it’s not always easy to access all the necessary equipment and supplies. In this blog post, we’ll explore whether or not you can weld stainless steel with standard MIG wire.

We’ll discuss the risks involved in using ordinary wire, the benefits of using correct wire for stainless steel, and provide tips for successful welding. Whether you’re a hobbyist or a professional welder, this post is for you.

So, put on your welding helmet and join us as we delve into the world of welding stainless steel.

What is MIG Welding?

Contents

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a fascinating welding process that creates an electric arc between a continuously fed wire electrode and the workpiece.

The wire electrode is spooled on a spool and fed through a MIG gun, which delivers the shielding gas to protect the weld from contamination by the surrounding air. MIG welding is an ideal option for those looking to weld materials like mild steel, stainless steel, and aluminum.

Its popularity in industrial settings is due to its speed, efficiency and ability to produce high-quality welds. Plus, it requires minimal preparation compared to other welding processes.

One of the advantages of MIG welding is that it can be automated, allowing for high-volume production. Additionally, MIG welding produces minimal slag and spatter, making cleanup time after welding a breeze.

However, it does require a steady hand and precise control of the welding gun’s speed and angle to achieve consistently good results. If you’re working with stainless steel, using a special MIG wire specifically made for welding stainless steel will result in stronger and more durable welds.

These wires are made from higher-quality materials with a higher nickel content than traditional MIG wire, allowing them to more closely match stainless steel’s physical characteristics. When working with any material, including stainless steel, it’s essential to ensure your welding machine is set up properly for the particular model and thickness of the material.

Additionally, be sure to clean and prepare your materials thoroughly before starting the welding process to prevent any dirt or grease from affecting your weld’s quality.

What is the Difference Between Normal MIG Wire and Specialty MIG Wire?

Normal MIG wire is made of mild steel which is perfect for general fabrication, construction, and automotive repairs. It can also be used to weld galvanized steel, which is challenging to weld with other welding processes.

However, specialty MIG wire is designed for specific materials and applications. For instance, stainless steel MIG wire is exclusively made for welding stainless steel, while aluminum MIG wire is meant for welding aluminum.

Each type of wire has distinct designs and features that make them suitable for their intended purposes. The primary difference between the two types of wires lies in the composition of the shielding gas used.

Standard MIG wire uses a blend of argon and carbon dioxide as shielding gas, while specialty MIG wire may require different mixtures or pure gases depending on the material being welded. Additionally, normal MIG wire comes in larger diameters than specialty MIG wire, making it ideal for high deposition rates and increased productivity.

However, this means it may not be suitable for welding thinner materials or applications that require precision and control. Therefore, when choosing a MIG wire, it’s crucial to consider the material being welded and select the appropriate wire for the task.

While normal MIG wire can be used for various applications, it may not be suitable for welding stainless steel or other specialized materials. Specialty MIG wire is specifically designed for these materials and offers superior performance and results.

Whether you’re a seasoned welder or just starting out, understanding the differences between normal MIG wire and specialty MIG wire can help you select the right tool for the job.

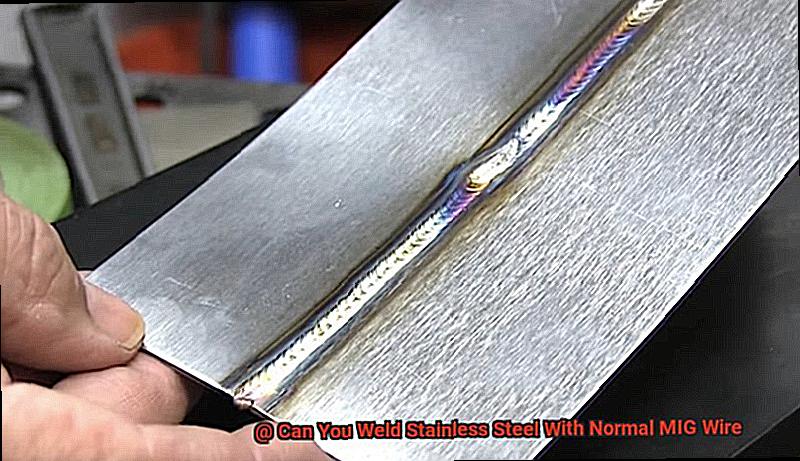

Can You Weld Stainless Steel With Normal MIG Wire?

Welding stainless steel is not as simple as using any old wire.

It requires a specific type of wire to get the job done right. MIG welding is one of the most popular methods for welding stainless steel, but using normal MIG wire for this task is a no-go.

The reason for this is that stainless steel has unique properties compared to other metals, like mild steel. This metal has a higher percentage of chromium, which makes it corrosion-resistant, but it requires a specific type of wire to be welded properly.

Stainless steel MIG wire is the key component needed to successfully weld stainless steel. This specialized wire contains higher levels of nickel or chromium, which helps ensure that the weld is strong and corrosion-resistant.

Using regular MIG wire to weld stainless steel can lead to weak welds that break under stress and rust over time due to a lack of corrosion resistance. Think of it like trying to bake a cake with regular flour for a gluten-free recipe.

The properties are different, and you won’t get the desired result. Similarly, using standard MIG wire to weld stainless steel will not produce the results you want.

Advantages of Using Specialty MIG Wire for Welding Stainless Steel

Welding stainless steel is like creating a culinary masterpiece, and just as you need the right ingredients for baking, you need a special MIG wire designed specifically for welding stainless steel.

In this blog post, we’ll explore the advantages of using specialty MIG wire for welding stainless steel. Firstly, specialty MIG wire is made from a higher grade of stainless steel than regular MIG wire, making it more resistant to corrosion and able to withstand higher temperatures.

It’s like using high-quality ingredients in your recipe; the end result will be stronger and more durable. But that’s not all: specialty MIG wire also contains additives that help produce a more stable arc, resulting in cleaner welds with less spatter.

It’s similar to using a good mixer instead of mixing by hand; you’ll end up with a smoother and more consistent batter or weld. Another benefit of using specialty MIG wire is that it produces more consistent and predictable welds.

The wire is manufactured to strict tolerances, ensuring uniform diameter and chemical composition, which allows the welder greater control over the welding process. It’s like following a recipe when cooking; you know exactly what you’re going to get.

Additionally, specialty MIG wire often comes in smaller spools than regular MIG wire, making it more cost-effective for small welding jobs or hobbyist use. You can buy only the amount of wire needed for the job, rather than having to purchase a large spool of regular MIG wire that may go unused.

FraGLyZUueM” >

Other Factors to Consider When Welding Stainless Steel

Welding stainless steel is an art that requires precision, focus, and the right materials.

While using a special MIG wire made exclusively for welding stainless steel is a good start, it’s not enough. To ensure a clean, strong, and durable weld, several other factors must be considered.

One of the most critical aspects to consider is the shielding gas used during the welding process.

Stainless steel requires a specific type of shielding gas to prevent oxidation and ensure a clean weld.

The most commonly used gas for welding stainless steel is a blend of argon and carbon dioxide.

Without proper shielding gas, the weld will be fragile and vulnerable to cracking.

Another vital factor to consider is the type of filler metal used. Using normal MIG wire may seem like a good idea, but it can result in a fragile or brittle weld that is prone to cracking.

Stainless steel requires a special type of filler metal called ER308L, which has higher chromium and nickel content than standard MIG wire. Failing to use the correct filler metal can jeopardize the strength and tenacity of the weld.

The thickness of the stainless steel being welded also plays a crucial role in the welding process. Thicker pieces of stainless steel require more heat and a slower welding speed to ensure proper penetration and fusion.

On the other hand, thinner pieces of stainless steel require less heat and a faster welding speed to prevent warping or burn-through. Proper cleaning and preparation of the surface before welding are critical as well.

Any contaminants or oxidized areas can lead to poor weld quality or even failure. Stainless steel should be cleaned with a wire brush or grinder prior to welding, and any oil or grease should be removed with a degreaser.

Each element, from shielding gas to filler metal to thickness and surface preparation, plays a vital role in creating a strong and durable weld.

Also Read: Can You Weld Chromoly To Mild Steel?

Conclusion

Welding stainless steel is a valuable skill that requires expertise and precision.

If you’re looking to expand your welding capabilities, it’s essential to understand the importance of using the right equipment for the job. While MIG welding is a popular technique used by many welders, using normal MIG wire for welding stainless steel is not recommended.

Normal MIG wire lacks the necessary corrosion resistance required for welding stainless steel, resulting in weak welds that may break under strain and rust over time. However, specialty MIG wire made explicitly for welding stainless steel provides superior performance and results.

This type of wire contains higher amounts of nickel or chromium, which ensures robust and corrosion-resistant welds. Apart from using the right wire, other critical factors must be considered when welding stainless steel.

These include the type of shielding gas used, filler metal used, material thickness, and surface preparation. Proper surface cleaning and preparation are essential before welding to ensure clean and durable welds.

In summary, choosing the right equipment is crucial in producing strong and long-lasting welds when working with stainless steel.