Are you frustrated with a cracked or broken aluminum part that needs to be fixed ASAP? Look no further than JB Weld. This specialized epoxy is known for its strength and versatility, making it a go-to solution for many DIY projects. But the question remains: can JB Weld work on aluminum?

Aluminum is notoriously difficult to bond due to its non-porous nature, but JB Weld has been known to successfully create a strong, durable seal on aluminum surfaces. However, not all JB Weld products are created equal when it comes to bonding with aluminum. It’s important to choose the right product for your specific needs.

In this post, we’ll dive into whether JB Weld works on aluminum and explore the different types of JB Weld available. We’ll also provide tips and tricks for proper application to ensure the best possible results. So if you’re wondering whether JB Weld can fix your aluminum woes, keep reading – we’ve got you covered.

Does JB Weld Work on Aluminum?

Contents

If you’re looking for an adhesive to bond aluminum, you might be wondering if JB Weld is up to the task. The good news is that JB Weld can work on aluminum – but it’s important to follow some guidelines to ensure a strong and lasting bond.

The first thing to keep in mind is that not all JB Weld products are suitable for use on aluminum. The company offers different types of epoxy adhesives, each formulated for specific applications and materials. So, it’s crucial to select the right product that is designed for use on aluminum surfaces.

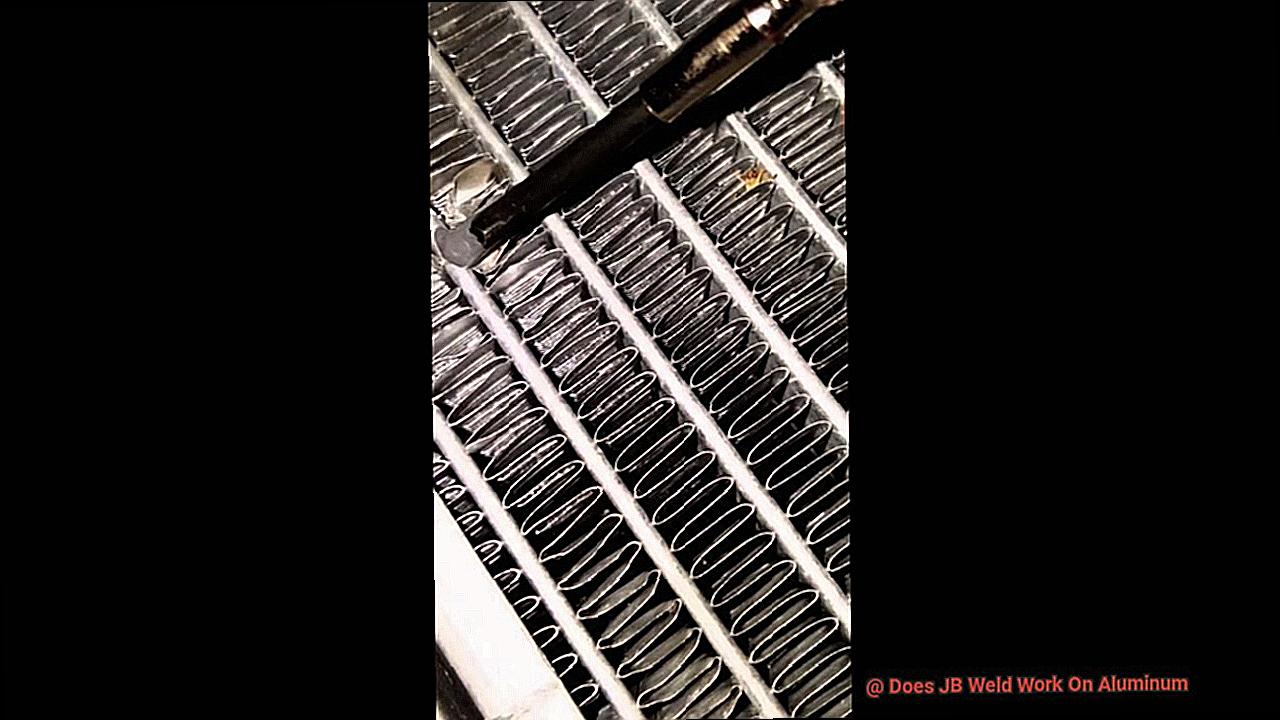

Once you’ve selected the appropriate JB Weld product, the next step is to prepare the aluminum surface. This involves ensuring it’s clean, dry, and free of any contaminants like oil or grease. You can also enhance adhesion by roughening the surface with sandpaper or a wire brush.

Applying the JB Weld correctly is equally important. The two-part epoxy adhesive needs to be mixed thoroughly according to the instructions provided by the manufacturer. Then, apply it in a thin layer using a putty knife or similar tool. Be sure to wipe away any excess adhesive before it dries.

Finally, be patient and allow enough time for the JB Weld to cure fully before using the repaired aluminum part. This will depend on various factors such as the type of JB Weld product used, temperature, humidity, and thickness of the adhesive layer. It’s recommended to follow the manufacturer’s instructions carefully and allow sufficient curing time before using the repaired part.

Remember, selecting the right product, preparing the surface correctly, applying the adhesive precisely, and allowing enough curing time are all essential for achieving a strong bond between aluminum surfaces with JB Weld. By following these guidelines, you’ll be able to trust that your repair will last for years to come.

Types of JB Weld Suitable for Aluminum Bonding

If you want to bond aluminum surfaces, it’s crucial to use the right type of JB Weld product. As an expert in this field, let me guide you through the different options available for aluminum bonding.

The original JB Weld product is versatile and robust, but it’s not recommended for aluminum surfaces. Aluminum has a unique tendency to expand and contract more than other metals, potentially weakening the bond over time. What are your alternatives?

JB Weld AluminumWeld is specifically formulated for lightweight metals such as aluminum, magnesium, and zinc. Its water and chemical resistance makes it ideal for harsh environments where strength is a must.

Need an adhesive for high-temperature environments? Try JB Weld ExtremeHeat, which can withstand temperatures up to 2400 degrees Fahrenheit. Although not designed exclusively for aluminum bonding, it can be used on various metals, including steel, copper, and brass.

For those who value aesthetics in their projects, JB Weld ClearWeld is an excellent option. This clear epoxy can be used on a range of surfaces, including aluminum. Although it may not be as strong as some of the other products mentioned, it’s perfect for projects where appearance matters.

When selecting a JB Weld product for your aluminum bonding needs, consider factors such as strength, temperature resistance, and chemical resistance. By choosing the right product for the job, you can ensure a strong and durable bond between your aluminum surfaces.

In conclusion, JB Weld offers several products suitable for aluminum bonding that cater to a variety of needs. Whether you need an adhesive that resists water and chemicals or one that endures high temperatures, there’s a JB Weld product that will meet your requirements.

How to Use JB Weld Aluminum Epoxy

Look no further than JB Weld Aluminum Epoxy. This versatile and reliable product can withstand high temperatures and harsh environments, making it perfect for repairing aluminum objects. However, to use it effectively, you need to follow these five simple steps:

Step 1: Prepare the surface.

Before applying the epoxy, make sure the surface is clean, dry, and free of any dirt, grease, or oil. Use sandpaper or a wire brush to remove any rust, paint or debris.

Step 2

Mix the epoxy. JB Weld Aluminum Epoxy comes in two parts – resin and hardener. Mix equal parts of both components together until they blend into a uniform color.

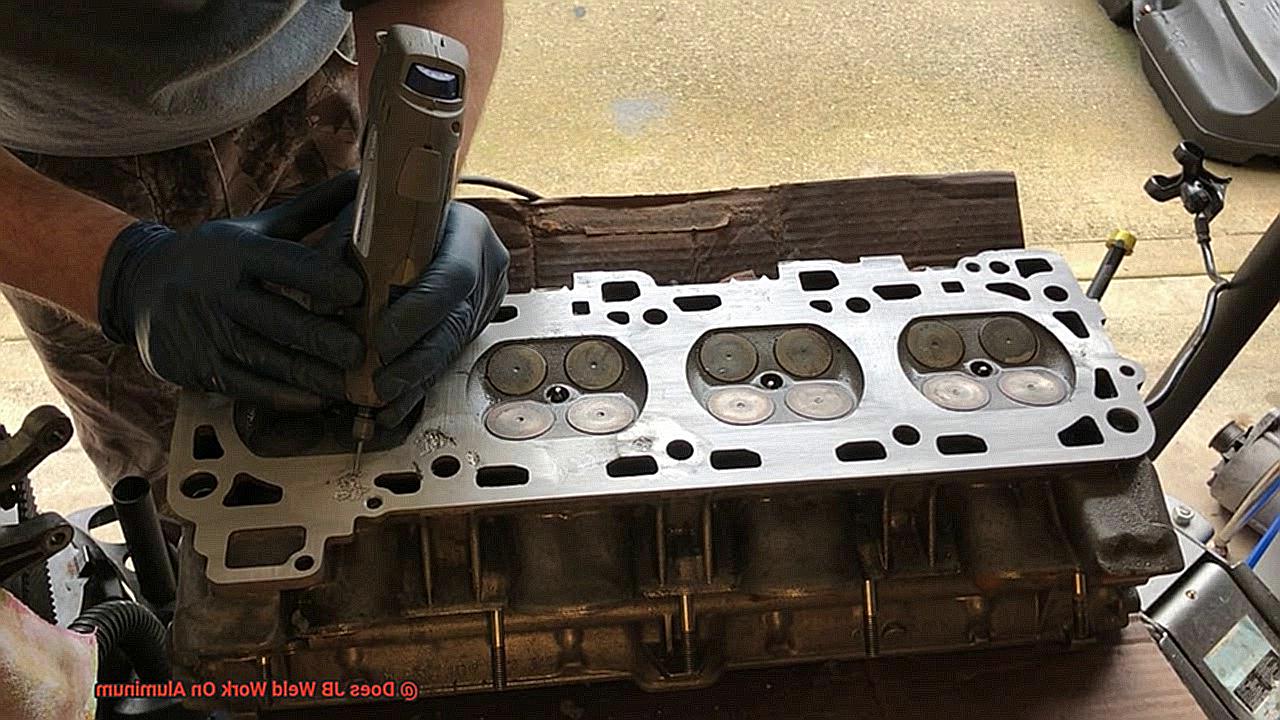

Step 3: Apply the epoxy.

Use a putty knife or similar tool to apply the epoxy onto the surface you want to repair. Ensure that the layer is even and covers the entire area of the repair.

Step 4: Let it cure.

After applying the epoxy, let it cure for at least 24 hours before using it again. Keep in mind that curing time can vary depending on temperature and humidity.

Step 5: Sand and paint.

Once the epoxy has cured, you can sand it down to a smooth finish and paint over it if necessary.

It’s important to note that JB Weld Aluminum Epoxy is not suitable for all repair applications. For large repairs or those under constant stress or pressure, it may be best to seek professional welding services instead.

Additionally, while this product is effective for filling gaps and cracks in aluminum surfaces, it’s not recommended for structural repairs or repairs where high strength is required.

Advantages of Using JB Weld Aluminum Epoxy

One of the primary benefits of using JB Weld Aluminum Epoxy is its impressive strength. With a tensile strength of 5020 PSI, this epoxy can handle heavy loads and high-stress environments with ease. You can trust it to keep your repairs strong and secure.

But strength isn’t the only advantage of JB Weld Aluminum Epoxy. This product can also withstand extreme temperatures up to 500°F, making it perfect for high-heat applications. And with its resistance to water, oil, and chemicals, you won’t have to worry about it breaking down or deteriorating over time.

What really sets JB Weld Aluminum Epoxy apart from other products is its versatility. It can be used on a variety of surfaces, including aluminum, brass, bronze, copper, stainless steel, and more. Whether you’re working on automotive repairs or household tasks, this epoxy is a reliable solution that can handle any job.

Ease of use is also a major advantage of JB Weld Aluminum Epoxy. Its two-part system requires mixing before application, but once mixed, the epoxy is simple to apply using a brush or spatula. Even novice welders can use this product with confidence and ease.

Overall, JB Weld Aluminum Epoxy is a reliable and versatile solution for any welding application. Its strength, temperature resistance, chemical resistance, versatility, and ease of use make it an excellent choice for any repair job.

Disadvantages of Using JB Weld Aluminum Epoxy

It’s important to note that this product also has some disadvantages worth considering.

One of the biggest drawbacks of JB Weld Aluminum Epoxy is its limited ability to withstand high temperatures. If exposed to temperatures over 500°F, the epoxy can break down, compromising the bond’s strength. This means it might not be suitable for use in automotive or industrial applications where high temperatures are common.

Another important factor to consider is that JB Weld Aluminum Epoxy may not adhere well to certain types of aluminum alloys. While it works well with most alloys, some high-strength alloys may not bond as effectively. Therefore, it’s crucial to check the manufacturer’s guidelines before using this product on specific types of aluminum alloys.

Furthermore, once applied, removing JB Weld Aluminum Epoxy can be challenging. This can make repairs or alterations difficult if the need arises. In some cases, users may need to use cutting tools to remove the epoxy, which can damage the underlying metal and create further difficulties.

In conclusion, while JB Weld Aluminum Epoxy is a reliable and effective product for welding aluminum, it’s essential to consider its limitations before use. As an expert in welding, I advise users to evaluate their project’s requirements carefully before selecting a welding solution.

Alternatives to Using JB Weld on Aluminum

There are three reliable alternatives that can provide you with a strong and reliable bond.

Firstly, the two-part epoxy method is a go-to solution for those who want an adhesive designed to bond with different materials, including aluminum. This powerful bonding agent does not contain any metal fillers like JB Weld. Once it dries, you can easily sand and paint over it for a clean finish.

For those who prefer hands-on techniques, specialized aluminum welding rods or wires could be your best bet. This technique involves using a TIG welder to melt the rod or wire onto the aluminum surface, creating a strong bond. However, it requires experience and skill with welding.

Lastly, you can opt for aluminum brazing rods. This method involves heating the aluminum surface and melting the brazing rod onto it to create a bond – similar to welding but with lower temperatures achievable with a propane torch. This method is not only effective but also offers greater flexibility in terms of the types of alloys that can be bonded.

While JB Weld may work in some cases, it’s always good to have alternative options available. By considering these alternatives, you can choose the best method for your specific project needs and ensure a strong and reliable bond.

rAcDTs1MpKY” >

Conclusion

To sum up, JB Weld is a dependable and adaptable epoxy adhesive that can be used effectively on aluminum surfaces.

It’s crucial to choose the right product for your particular needs and follow the proper application techniques to achieve a sturdy and long-lasting bond. Not all JB Weld products are created equal when it comes to bonding with aluminum, so it’s essential to select the right one.

When it comes to bonding with aluminum, JB Weld AluminumWeld is specially designed for lightweight metals like aluminum, magnesium, and zinc. JB Weld ExtremeHeat can handle high temperatures up to 2400 degrees Fahrenheit, while JB Weld ClearWeld is an excellent option for projects where appearance matters.

While using JB Weld Aluminum Epoxy has its advantages such as impressive strength, versatility, temperature resistance, chemical resistance, and ease of use; there are also some drawbacks worth considering. Its limited ability to withstand high temperatures over 500°F and difficulty in removing once applied are some disadvantages.

If you’re looking for alternatives to using JB Weld on aluminum surfaces, you can consider the two-part epoxy method or specialized welding rods or wires. Aluminum brazing rods offer greater flexibility in terms of the types of alloys that can be bonded.