Are you tired of hauling around bulky and cumbersome welding equipment?

Well, prepare to be amazed as we delve into the world of the Lincoln 225 welder. This mighty yet compact machine has been a go-to for welders for years, earning a well-deserved reputation for its versatility and power.

So let’s roll up our sleeves and take a closer look at just how much this bad boy weighs and how it can affect your welding journey.

How Much Does A Lincoln 225 Welder Weight?

Contents

- 1 How Much Does A Lincoln 225 Welder Weight?

- 2 The Specifications of a Lincoln 225 Welder and Its Weight

- 3 How Does the Weight of the Lincoln 225 Compare to Other Welders?

- 4 Considering Your Needs: Is the Weight of the Lincoln 225 Manageable for You?

- 5 Size and Design: How Does It Contribute to the Overall Weight?

- 6 The Type of Welding Process Used in the Lincoln 225 and Its Impact on Weight

- 7 Tips for Handling and Transporting a Heavy Welder like the Lincoln 225

- 8 Conclusion

When it comes to the art of welding, having the right tools is essential for a successful and efficient job. One popular choice among skilled welders is the powerful and adaptable Lincoln 225 welder. This dependable machine has been a trusted companion in many workshops and garages for years. However, a common inquiry that arises when considering purchasing this machine is, “How much does a Lincoln 225 welder weigh?” In this blog post, we will delve into the weight of this welding machine and its impact on your welding tasks.

According to the manufacturer’s specifications, the weight of the Lincoln 225 welder is approximately 109 pounds (49 kg), including its accessories. This figure holds great significance as it can greatly affect your transportation, setup, and safety plans when using this machine.

To begin with, knowing the weight of a welding machine is crucial for transportation purposes. As an experienced welder, you may find yourself needing to relocate your machine to various job sites or projects. Being aware of its weight can assist you in planning accordingly and ensuring that you have all the necessary equipment to transport it safely.

The weight of a welding machine also plays a vital role in setting up and positioning. Some welding tasks require the machine to be placed on a stable surface or mounted on a workbench. By understanding its weight, you can determine if your work surface is capable of supporting it and make any necessary adjustments.

But that’s not all; the weight of a welding machine can also provide insight into its durability and construction. A heavier machine may signify better quality materials and components, which can ultimately affect its performance and longevity.

In addition to these factors, being aware of the weight of a welding machine is crucial for safety precautions. A heavier machine may require more effort to move, which means employing proper lifting techniques is imperative to prevent injuries.

Furthermore, considering the weight of a welding machine is critical when making purchasing decisions.

The Specifications of a Lincoln 225 Welder and Its Weight

The weight of a welder can make or break the welding experience. And when it comes to the ultimate welding machine, the Lincoln 225 welder takes the cake. Its reputation for powerful stick welding, sturdy construction, and user-friendly interface has made it a household name among welders. But what exactly are the specifications of this beast? And how much does it tip the scales?

First, let’s delve into the nitty-gritty details. The Lincoln 225 welder is specifically designed for stick welding, making it a top choice for tackling thicker materials. With its front-mounted AC/DC polarity switch, switching between welding modes is a breeze. This feature not only allows for seamless transition between AC and DC welding processes but also makes it a versatile tool for various welding projects. The cherry on top? Its smooth arc guarantees precise and immaculate welds.

But let’s talk about power. The Lincoln 225 welder boasts an impressive input power of 240 volts and a maximum output of 225 amps. In simpler terms, it can handle anything from minor touch-ups to heavy-duty projects with ease. And with a duty cycle of 20% at 225 amps and a whopping 100% at 75 amps, this machine is built to work hard and deliver exceptional results.

Now, let’s address the elephant in the room: its weight. The Lincoln 225 welder weighs approximately 109 pounds (49 kg). While this may seem like a hefty load to bear, it is relatively lightweight compared to its industrial-grade counterparts. With dimensions of 26 x 14 x 18 inches (66 x 36 x 46 cm), it is also compact enough to move around and store in different work environments effortlessly.

For professional welders and DIY enthusiasts alike, the weight and dimensions of a welding machine are crucial factors to consider.

How Does the Weight of the Lincoln 225 Compare to Other Welders?

When it comes to welding, the mass of a machine may not be the foremost thought in one’s mind. Nonetheless, for both experts and enthusiasts, the heaviness of a welder can make a substantial difference in terms of portability and convenience. So, how does the weight of the Lincoln 225 compare to other welders in its league? Let’s explore.

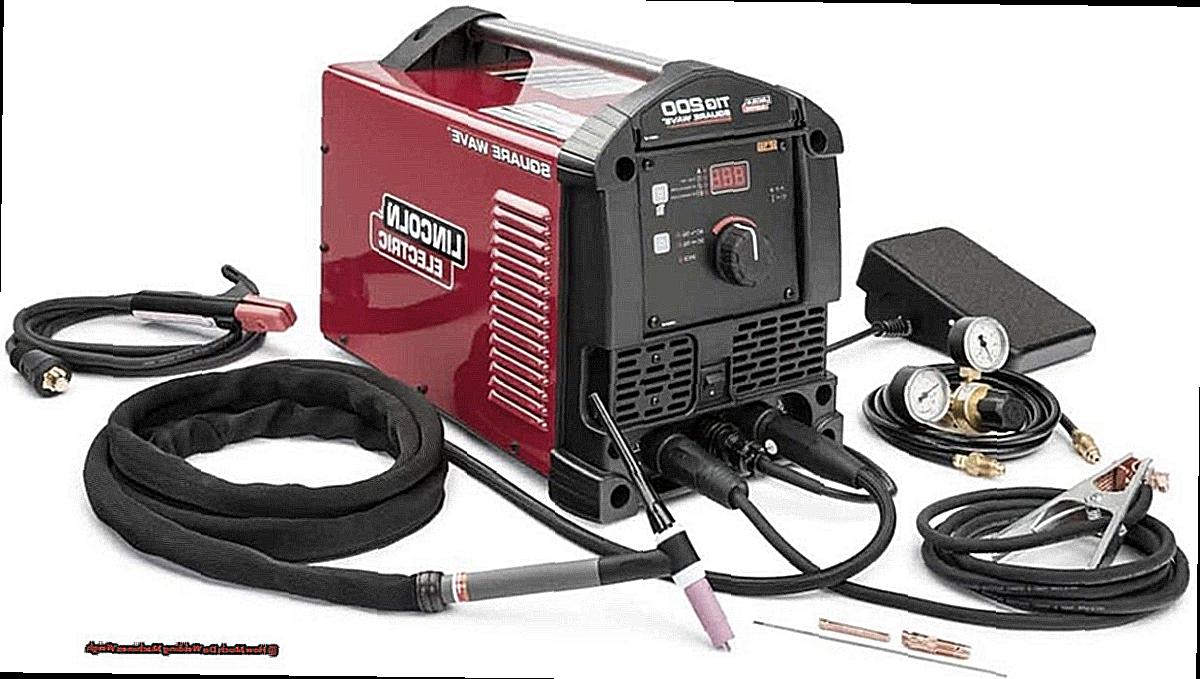

The Lincoln Precision TIG 225 welder is a product of the distinguished company, Lincoln Electric. With its fusion of advanced technology and robust construction, this welder is a top pick for both professionals and hobbyists. Tailored specifically for TIG and stick aluminum welding, it offers a vast array of settings to achieve precise outcomes.

One of the most notable features of this machine is its Micro-Start II function, which provides superior arc stability and initiation. This is particularly advantageous for novices who may struggle with starting an arc. Additionally, the TIG pulser function aids in reducing distortion, resulting in cleaner and more accurate welds.

Now, let’s turn our attention to its weight. At 192 pounds, the Lincoln 225 may seem weightier than other models on the market. However, bear in mind that this welder is designed for professional use and boasts a potent transformer-based design. While this may contribute to its mass, it also ensures high-quality and durable welds.

But is the weight justified? Absolutely. The Lincoln Precision TIG 225 has established itself as a trustworthy workhorse in the world of welding. Its heavy-duty construction enables it to tackle any project with ease and precision, making it a worthwhile investment for professionals.

Moreover, regular maintenance every three months guarantees optimal performance and prolongs the lifespan of this machine. Not to mention, with a limited warranty from Lincoln Electric covering various parts for different durations, you can rest assured that your investment is safeguarded.

Considering Your Needs: Is the Weight of the Lincoln 225 Manageable for You?

Look no further than the Lincoln Electric AC 225 Arc Welder. With its smooth and efficient AC arc and ability to work with a diverse range of metals, this model has been hailed as a top pick for four decades. But what about its weight? As an expert in the field, you understand the weight of a welder can be a critical factor in its usability. So, let’s delve into the specifics and determine if the Lincoln 225 is manageable for your specific needs.

Firstly, let’s discuss its portability. At a weight of 113 pounds, this welder may not be the lightest option available, but it is still considered portable. Its compact design and sturdy handle make it convenient to transport to various job sites or around your workshop. And with a powerful output of 225 amps, it is well worth carrying that extra weight.

But what about its capabilities? The Lincoln AC 225 is renowned for its versatility in working with a variety of metals, making it suitable for home, farm, and industrial use.

Additionally, it is equipped with external thermal protection, ensuring it can handle even the most intricate tasks such as bridge building or construction projects. And with a long power cord and a 3-year warranty, you can trust that this welder will withstand the test of time.

So, to address the question – yes, the weight of the Lincoln 225 is manageable for all your welding needs. Its power, durability, and portability make it a top choice among professionals and hobbyists alike.

Size and Design: How Does It Contribute to the Overall Weight?

In the world of welding, having the right equipment is crucial for achieving optimal results. For over five decades, one welder has stood the test of time and earned a loyal following among professionals and DIY enthusiasts alike – the Lincoln Electric AC-225 stick welder.

But what sets this compact machine apart from the rest? Let’s delve into the impact of its size and design on its overall weight and discover why it has become a staple for so many individuals.

Compact Design: Portability Perfected

One of the most significant selling points of the Lincoln Electric AC-225 stick welder is its compact design. Weighing 113 pounds, it may not be the lightest option available, but its sturdy handle makes it easy to transport to any job site or workshop.

This feature is especially valuable for those who frequently move their welding equipment, such as farmers or contractors working on multiple projects.

Despite its relatively small size, this welder packs a powerful punch with its 40-225 amp range. This means it can handle electrodes up to 3/16 in. for carbon steel and 5/32 in. for other materials, making it versatile enough for various welding tasks.

Rectifier-Based Technology: Smooth Arcs and Precision Welds

Another reason for the popularity of the AC-225 is its rectifier-based technology. This advanced feature allows for a smooth AC arc, resulting in precise and clean welds even on challenging materials. This advantage is especially beneficial for beginners learning how to weld, as it enables them to achieve better results with less effort.

And let’s not overlook the durability of this machine. With external thermal protection and a long power cord, it’s built to withstand even the toughest tasks. This means you can trust this welder to perform at its best consistently.

The Type of Welding Process Used in the Lincoln 225 and Its Impact on Weight

Are you in the market for a high-quality welding machine that can handle even the toughest tasks with ease? Look no further than the Lincoln Electric AC 225 Arc Welder. This powerful and adaptable machine is a top pick among professionals, thanks to its advanced stick welding process and impressive array of features.

But what sets the welding process used in the Lincoln 225 apart? Let’s delve into its impact on weight and explore why it has become the go-to option for welders worldwide.

The Advantages of Stick Welding

Also known as shielded metal arc welding (SMAW), stick welding is a preferred method for its ability to produce robust welds and handle thicker materials. This makes it ideal for heavy-duty tasks and industrial applications. The Lincoln 225 takes stick welding to new heights with its advanced technology and innovative features.

Unmatched Versatility

One of the standout features of the Lincoln 225 is its broad range of welding amperage options. This allows for versatility in welding various types of metals, including cast iron, steel, and stainless steel. No matter the project at hand, this machine has you covered.

Guaranteed Quality Assurance

Professionals demand equipment they can trust, which is why the Lincoln 225 is manufactured under ISO 9001 requirements for quality assurance. This ensures that every machine meets high standards and is built to withstand the test of time. The machine also comes with a 3-year warranty, providing peace of mind in your investment.

Unrivaled Performance for Heavy-Duty Tasks

The Lincoln 225’s formidable performance makes it suitable for even the most demanding tasks, such as welding thick pipes. Its external thermal protection prevents overheating, while the lengthy power cord ensures safe and efficient operation. Plus, its portability allows you to tackle welding projects anywhere, from your workshop to remote locations.

Tips for Handling and Transporting a Heavy Welder like the Lincoln 225

Welding is a vital skill in many industries, and having the right equipment is crucial in achieving high-quality results. However, modern welding machines can be quite expensive, making them unattainable for some.

That’s where basic AC stick welders, also known as “tombstones,” come in handy. These machines may be great for learning how to lay a bead, but they do have their limitations. But don’t worry, with some ingenuity and clever modifications, you can transform your basic AC stick welder into an AC/DC welder with TIG capabilities, just like expert welder Greg Hildstrom did.

Greg Hildstrom saw the potential to enhance his welding capabilities without breaking the bank. He decided to hack his AC stick welder, specifically the Lincoln 225 model, and transform it into an AC/DC welder with TIG capabilities. His modifications included utilizing three extension cords to create a larger conductor and incorporating rectifiers and a choke from a microwave oven transformer for DC output. He also devised homemade foot pedals for voltage control and added industry-standard connectors for easy use.

With the help of a vintage Lincoln “Hi-Freq” controller, Greg successfully turned his basic AC stick welder into a versatile machine that can handle various projects, including creating an electric arc furnace.

When handling and transporting heavy welders like the Lincoln 225, it’s crucial to take proper safety precautions. These machines are hefty and can be challenging to maneuver, so it’s essential to follow these tips to ensure your safety and that of others:

Use correct lifting techniques: When lifting the welder, remember to bend your knees and use your leg muscles instead of your back. It’s also helpful to have a partner assist you in carrying the machine.

Conclusion

In summary, the Lincoln 225 welder is a formidable force in the world of welding, renowned for its versatility and strength. We have delved into its weight and how it can impact your welding journey, from transportation to setup and safety precautions.

At approximately 109 pounds (49 kg), this machine may seem heavy at first glance, but compared to its industrial-grade counterparts, it is relatively lightweight. Its compact design and sturdy handle make it easy to transport, while its impressive output of 225 amps makes it suitable for a wide range of welding tasks.

Furthermore, we have compared the weight of the Lincoln 225 to other welders in its class, such as the Lincoln Precision TIG 225 and the Lincoln Electric AC-225 stick welder. While these machines may be heavier, their durability and performance justify their weight.

Additionally, we have discussed how the type of welding process used in the Lincoln 225 can affect its overall weight. Stick welding is preferred for producing strong welds on thicker materials, making it perfect for heavy-duty tasks.

Lastly, we have shared tips on handling and transporting a bulky welder like the Lincoln 225 safely. It’s crucial to use proper lifting techniques and have a partner assist you when carrying the machine.

In conclusion, if you’re tired of lugging around unwieldy and cumbersome welding equipment, look no further than the Lincoln 225 welder. With its manageable weight and impressive capabilities, this machine will undoubtedly become your go-to tool for all your welding needs.