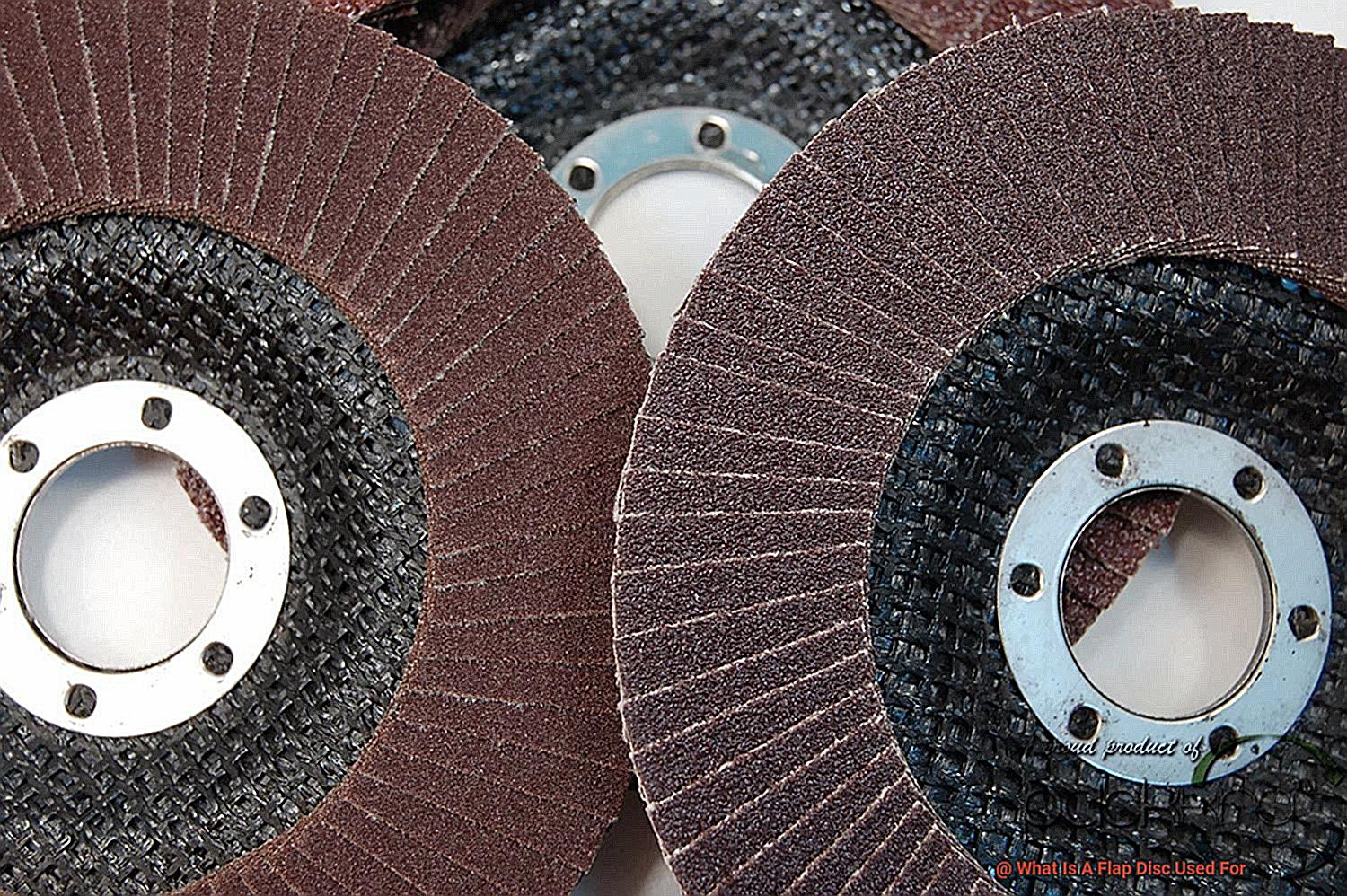

Have you ever come across a tool that looks like a small fan with overlapping sheets of sandpaper? Well, that’s a flap disc. These disc-shaped tools have gained immense popularity in the world of metalworking and carpentry for their versatility and ease of use.

Flap discs are designed to be fitted onto a grinder, making them ideal for smoothing and finishing metal, wood, or other materials. Their unique overlapping design allows the fan-shaped discs to contour easily to the workpiece, ensuring consistent and accurate sanding.

Deburring, grinding, and finishing tasks are some of the common uses of flap discs. They can remove rust, paint or coatings while shaping or polishing various surfaces. Flap discs are perfect for projects that require precision and accuracy such as restoring old furniture or preparing a car body for painting.

Whether you’re an experienced professional or a novice DIYer, having flap discs in your toolkit is essential. Understanding their functions and applications can open up endless possibilities for your next project. So why not grab a flap disc today and take your sanding game to the next level?

What Is A Flap Disc?

Contents

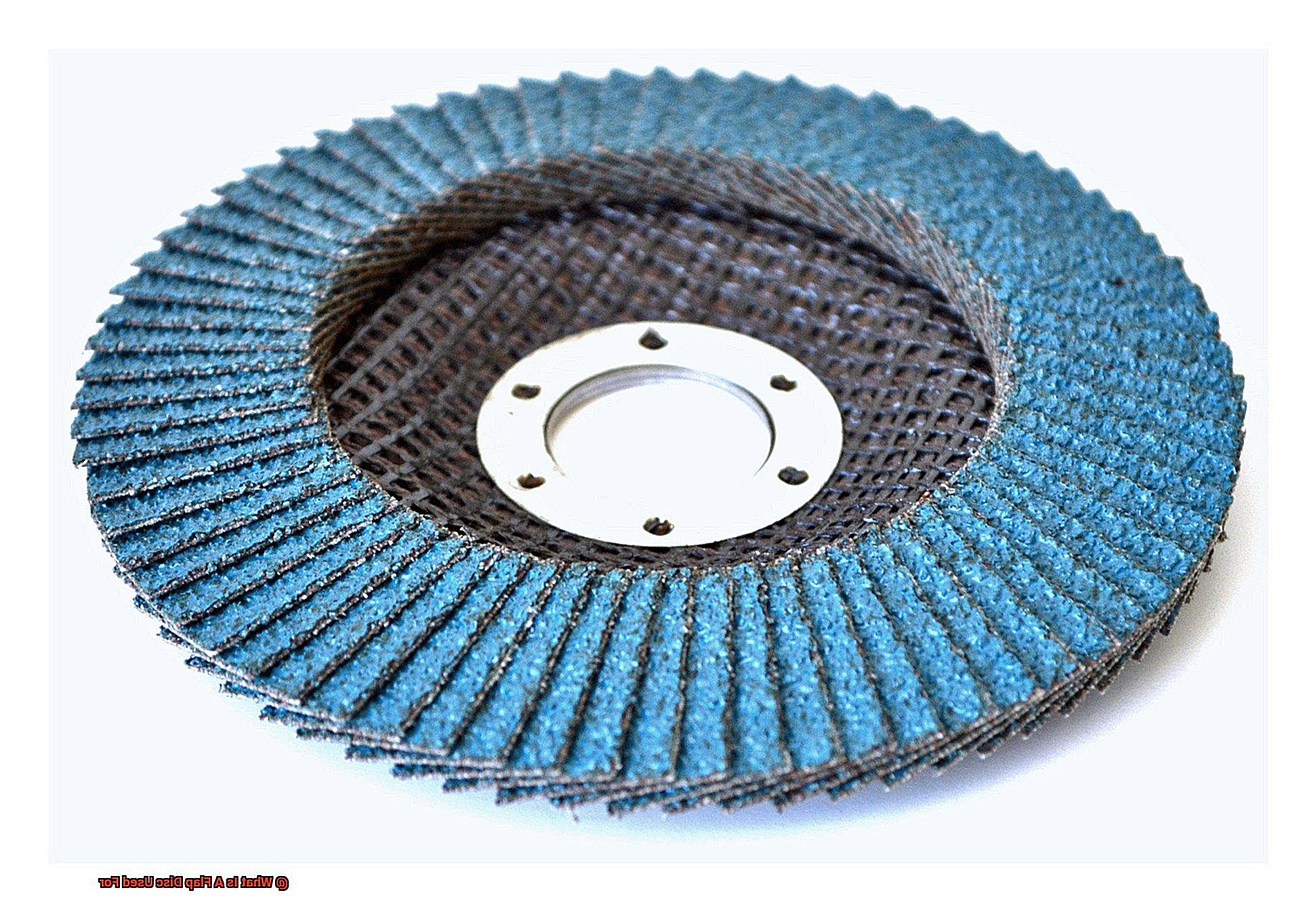

If you’re looking for a versatile, durable, and effective abrasive tool, look no further than the flap disc. But what exactly is a flap disc? Simply put, it’s a disc-shaped tool comprised of multiple overlapping layers of abrasive cloth or paper arranged around a central hub. These layers are made up of materials such as aluminum oxide, zirconia alumina, or ceramic grains that determine the abrasive properties of the disc.

One of the most common uses for flap discs is grinding and finishing operations on metal surfaces. They can remove rust, paint, and other surface coatings, as well as deburr and smooth rough edges. Flap discs are also incredibly useful for welders as they can effectively remove weld spatter and blend welded seams with ease.

But don’t think that flap discs are limited to metalworking applications. They can be used on wood and plastic surfaces too, as long as the appropriate grit size and material are used to avoid damaging the workpiece.

What makes flap discs truly unique is their ability to conform to irregular surfaces without damaging the workpiece. This makes them perfect for use on curved or contoured surfaces that traditional grinding wheels simply can’t handle. And with a range of grit sizes available, from coarse to fine, you’ll have the perfect tool for every level of material removal required.

Another significant advantage of flap discs is their extended use and consistent performance throughout their life. As the abrasive flaps wear away gradually during use, fresh abrasive material is exposed underneath, ensuring consistent performance until the disc is worn out.

Types of Flap Discs

If you want to achieve top-notch results in your grinding or finishing project, you need to have the right tools for the job. And when it comes to flap discs, there are various types available, each with its unique features and benefits. As an expert on this subject matter, I’m here to guide you through the different types of flap discs so that you can choose the perfect one for your specific needs.

Let’s start with ceramic flap discs, which are the most durable and long-lasting type available. These discs are perfect for heavy-duty grinding tasks, such as removing welds, rust, and paint. Additionally, ceramic discs are heat-resistant, which makes them an excellent option for grinding on hard metals like stainless steel.

Next up, we have zirconia flap discs, which are known for their high-performance capabilities. They can grind through tough materials quickly and efficiently and are ideal for use on mild steel, cast iron, and other metals.

If versatility is what you’re after, then aluminum oxide flap discs are the way to go. These discs can be used on a variety of materials like wood, plastic, and metal. Plus, they’re affordable and widely available.

Lastly, silicon carbide flap discs are specialty discs designed specifically for use on concrete and stone surfaces. They feature a unique abrasive grain that makes them perfect for grinding on hard materials.

Apart from these common types of flap discs, there are also specialty options available for specific applications. For instance, some flap discs come with a flexible backing that allows them to conform to curved surfaces easily. Others have a coating that prevents loading when working with soft materials like aluminum.

Benefits of Using a Flap Disc

If you’re accustomed to using traditional grinding wheels or sanding discs, you might not be aware of the many benefits that flap discs have to offer.

First and foremost, flap discs are incredibly versatile – they can be used on a wide variety of surfaces and materials, including metal, wood, plastics, and ceramics. They’re also great for removing stubborn coatings like rust and paint. This means that you don’t need to switch between different abrasive tools for each task – a flap disc can handle it all.

One of the most significant advantages of using flap discs is their consistency. Traditional grinding wheels wear down unevenly over time, resulting in inconsistent results. Flap discs, on the other hand, wear down evenly throughout their lifespan. This means that you’ll get consistent results every time you use them. Say goodbye to uneven surfaces and rough edges.

Speed is another major benefit of using flap discs. These tools are designed to work quickly and efficiently, reducing the amount of time it takes to complete a task. Compared to sanding discs, which can take ages to achieve the same level of finish, flap discs are lightning-fast.

Durability is yet another advantage of using flap discs. They’re constructed from high-quality materials that are designed to withstand heavy use and abuse. In fact, they can last up to 10 times longer than traditional sanding discs. This makes them an incredibly cost-effective choice in the long run.

Finally, flap discs are incredibly easy to use. They’re lightweight and maneuverable, allowing you to work in tight spaces or hard-to-reach areas with ease. You don’t need to put in much effort to achieve great results.

Common Applications for Flap Discs

Flap discs are the ultimate multi-taskers of the abrasive world. From grinding and smoothing surfaces to welding preparation, deburring, finishing work, and even sharpening tools – these versatile discs can conquer a wide range of tasks with ease and efficiency.

When it comes to grinding and smoothing surfaces, flap discs are the go-to tool. They effortlessly remove rust, paint, and other coatings from metal, wood, and plastic surfaces, leaving them smooth and ready for the next step in your project.

Flap discs are also the ultimate sidekick for welding preparation. They help clean up welds, remove excess material, and prepare surfaces for welding. Trust us, your welds will be thanking you for using flap discs.

Deburring is another area where flap discs shine. They are experts at removing burrs from metal, plastic, and wood. These pesky burrs can be dangerous and uncomfortable to work with, but flap discs smooth out rough edges and sharp corners like a boss.

Finishing work can be a tedious task, but flap discs make it a breeze. Whether you want a smooth surface finish or a textured one, flap discs have got you covered. They work on metal, wood, and plastic surfaces to give you the perfect finish.

Last but not least, sharpening tools such as chisels and knives is another area where flap discs excel. They expertly remove small nicks and burrs from blades, leaving them sharp and ready for action.

Grit Sizes and Materials Used in Flap Discs

When it comes to flap discs, selecting the right grit size and material can make all the difference in achieving optimal performance and results. It’s like choosing the perfect tool for a specific job – the right flap disc can help you effortlessly grind, smooth, deburr, finish work, and sharpen tools with ease and efficiency.

Grit sizes are a crucial factor to consider when choosing a flap disc. Coarse grit sizes, like 36 grit, are perfect for heavy-duty applications that require aggressive material removal.

Think of it like a bulldozer – tough and rugged enough to handle rough edges or welds on metal surfaces.

Medium grit sizes, like 60 grit, are ideal for general-purpose applications that require moderate material removal and a smooth finish. This is like a reliable pickup truck – versatile enough to handle most tasks with ease.

Fine grit sizes, like 120 grit, are great for finishing applications that require a high level of surface finish. This is like a luxury car – sleek and polished with a smooth and uniform finish.

Finally, ultra-fine grit sizes, like 240 grit, are perfect for delicate applications that require minimal material removal and a high level of surface finish. This is like a delicate sports car – precise and requiring a gentle touch.

But grit size isn’t the only factor to consider when choosing flap discs; the materials used also play an important role in their performance.

Aluminum oxide is the most common material used in flap discs and is suitable for general-purpose applications on steel and other ferrous metals.

Zirconia alumina is more durable than aluminum oxide and is ideal for heavy-duty applications on stainless steel and other non-ferrous metals. Ceramic alumina is the most durable material used in flap discs and is suitable for high-performance grinding applications on hard metals such as titanium and Inconel.

And if you’re looking for the longest lifespan, diamond flap discs are the most expensive but offer unparalleled performance for grinding and polishing hard materials such as concrete, stone, and glass.

Therefore, whether you’re tackling a heavy-duty job or need a delicate touch, selecting the right grit size and material can help you achieve optimal results with ease and efficiency. With a little knowledge and the right flap disc in hand, you can be confident in your ability to tackle any task with finesse.

Working with Irregular Surfaces Using a Flap Disc

If you’re looking to tackle an irregular surface, don’t fret. The flap disc is here to save the day. Unlike traditional grinding wheels that struggle with uneven surfaces, flap discs are designed with overlapping flaps of abrasive material that can conform to the contours of your workpiece. It’s like having a flexible, adaptable tool in your toolbox.

To achieve the best results, choosing the right grit and backing material is key. For heavy stock removal, lower grit discs (around 40-60) are ideal, while higher grit discs (80-120) are better suited for finishing work. And when it comes to backing material, fiberglass is the way to go. It’s more durable and long-lasting than plastic, making it a better choice for tough jobs.

Now that you’ve selected the appropriate flap disc, it’s time to get started. Start at a low speed and gradually work your way up to prevent overheating or damaging the workpiece. Holding the disc at a slight angle to the surface and using light pressure allows the flaps to conform to the contours of your workpiece. Move the disc in a back-and-forth or circular motion to ensure even coverage.

Of course, safety should always be top of mind when using any tool. Be sure to wear appropriate eye protection and gloves to avoid any accidents or injuries. Before use, always read and follow all manufacturer instructions and guidelines.

UXXM6i3FJ5s” >

Conclusion

In summary, flap discs are an indispensable tool for anyone working with metal, wood, or plastic. Their innovative overlapping design allows them to contour easily to the workpiece, ensuring precise and consistent sanding every time.

Flap discs are versatile and can be used for a variety of applications such as deburring, grinding, finishing tasks, welding preparation, and even sharpening tools. They can remove rust, paint or coatings while shaping or polishing various surfaces.

With a range of grit sizes available from coarse to fine and materials such as aluminum oxide, zirconia alumina, ceramic grains or diamond available in the market; you can select the perfect tool for every level of material removal required.

One of the significant advantages of flap discs over traditional grinding wheels or sanding discs is their consistency throughout their lifespan. Even wear down of abrasive flaps results in consistent performance every time you use them. They are also lightweight and maneuverable allowing you to work in tight spaces or hard-to-reach areas with ease.

Flap discs are durable and cost-effective in the long run. Whether you’re an experienced professional or a novice DIYer, understanding the different types of flap discs available is essential to selecting the right one for your grinding or finishing task.

Ceramic, zirconia, aluminum oxide and silicon carbide are all excellent options with unique features and benefits. Working with irregular surfaces doesn’t have to be a headache either.