Welding is a crucial process used across industries to join components and structures.

But, did you know that welding often results in residual stress that can cause damage and failure in the weld joint? That’s where peening comes into play.

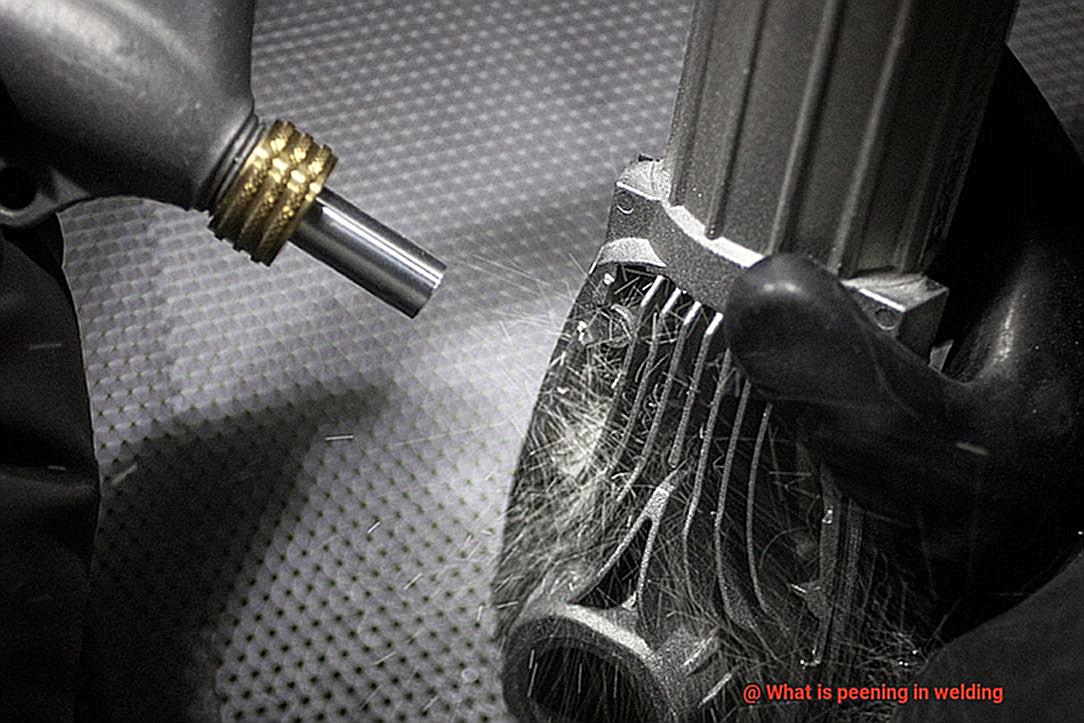

Peening is a post-welding process that involves striking the weld metal with a hammer or other materials like shot or glass beads. This technique creates compressive residual stress, which significantly enhances the strength and durability of the welding structure while reducing the possibility of fatigue failure.

But wait, there’s more. Peening also improves the aesthetic appeal of welding structures by reducing visible slag and spatter.

It creates a smoother surface, making it easier to apply a finishing coat for a polished look. Peening is applicable to various kinds of welding, including TIG, MIG, and stick welding.

It also works on both ferrous and non-ferrous metals, making it an incredibly versatile process. Whether you’re an engineer, welder or just curious reader, peening is an incredible post-weld process vital to ensuring the integrity and longevity of welding structures.

In this article, we’ll delve deeper into different types of peening processes, their benefits and when to apply them for optimal results.

What Does Peening Do to a Weld Bead?

Contents

Peening is a powerful process that can work wonders for your weld bead.

Imagine it as a rejuvenating spa day for your metal – it involves striking the surface of the material with a hammer or other tool to create a compressive force that helps to reduce residual stresses and improve the overall strength of the weld. When welding, the metal tends to contract as it cools, creating internal stresses that can lead to cracking or fatigue failure.

Peening comes to the rescue by inducing plastic deformation in the metal surface, redistributing any residual stresses present in the weld. This redistribution of stresses helps to prevent cracking and improves the weld’s fatigue resistance, resulting in a stronger, more durable joint.

But peening doesn’t just relieve stress – it also refines the grain structure of the metal, boosting its strength and toughness. By striking the metal surface, peening causes the grains to deform and realign themselves into a more uniform and refined structure.

This is especially useful in materials that are prone to cracking or fatigue failure. Peening isn’t just for improving welds – it can also be used to repair damaged or worn metal surfaces.

By striking the damaged area with a hammer or other tool, peening can help to smooth out any irregularities and restore the surface to its original shape. This is particularly valuable in applications where aesthetics or functionality are important.

It’s like treating your metal to a luxurious spa day – relieving stress and tension while refining its structure for optimal strength and toughness.

The Peening Process

Now, let’s explore the fascinating world of welding and the critical role that peening plays in creating strong, durable welds.

Think of peening as a spa day for your metal – it’s a process that involves striking the surface of a material with a hard object, such as a hammer, to create compressive stresses. In welding, peening is used to improve the quality and strength of the weld joint.

When we weld, heat is applied to the metal, which can cause significant distortion and residual stress. Peening helps to distribute these stresses more evenly throughout the material, reducing the risk of cracking, distortion, and other defects.

To perform peening, we use different types of peening tools such as ball-peen hammers, chisel-peen hammers, or air-powered peening guns. The choice of tool depends on the size and shape of the weld joint, as well as the type of metal being welded.

Peening should be done carefully and methodically, using light blows that are evenly spaced across the surface of the weld bead. It’s important to strike a balance between not enough and too much peening – under-peening may not provide enough compressive stress to improve the quality of the weld joint while over-peening can lead to excessive deformation and cracking.

The benefits of peening don’t stop at stress relief – it also helps to refine the microstructure of the weld metal, making it stronger and more resistant to fatigue. This is particularly important for thicker welds that need to withstand heavy loads or intense pressure.

Peening is an essential process in welding that can help to achieve high-quality weld joints. By creating compressive stresses in the material, peening can counteract tensile stresses that can cause welds to fail.

The Purpose of Peening a Weld

Have you ever wondered why welds can crack or fail over time, especially under high-stress conditions? Well, it all comes down to tensile stresses created during the welding process.

But don’t worry, peening is here to save the day. Peening is a crucial process in welding that involves striking the surface of the weld with a blunt object to improve its properties.

The purpose of peening a weld is to reduce those pesky tensile stresses and redistribute them into compressive stresses on the surface of the weld. This makes it more resistant to cracking and fatigue failure, ensuring the longevity of your welded components.

Think of it like a luxurious spa day for your metal – just as a good massage can relieve tension in your muscles, peening can relieve tension in your welded joints. By using a pneumatic hammer with a rounded tip or a ball-peen hammer, you can create overlapping dimples or indentations in the metal that help to smooth out any irregularities or rough spots on the surface.

But peening is not just about improving appearance – it’s recommended for high-stress applications such as pressure vessels, piping systems, and structural components. It can even improve the fatigue life of welded joints in machinery, vehicles, and other mechanical systems.

That’s right – a little bit of peening can go a long way in ensuring that your welded structures perform as intended and meet safety requirements over their intended service life. So next time you’re welding, don’t forget to give your metal some love with this essential process.

What is Meant by Peening in Welding?

It’s a fascinating process where the surface of a material is struck with a hammer or other tool to create compressive stresses.

It’s like giving your metal a spa day, allowing it to release any built-up tension and relax. Peening is commonly used in welding to improve the strength and durability of welds.

During the cooling process, a weld can create internal stresses that lead to cracking or distortion. Peening helps to relieve these stresses by introducing compressive forces that counteract the tensile forces created during welding.

To peen a weld, you’ll need a ball-peen hammer or pneumatic peening hammer. These tools strike the surface of the weld bead, creating small indentations that help to redistribute stresses within the material.

The pattern of peening is crucial as it ensures even distribution across the entire weld. The benefits of peening in welding are numerous.

Peening improves the fatigue life of welded structures, making them more resistant to failure over time. It also reduces distortion and prevents cracking in critical areas of the weld.

Additionally, peening helps to improve the appearance of the weld by smoothing out any rough edges or irregularities. It’s essential to use the correct technique and equipment when peening a weld.

Peening should be done while the weld is still hot but not too hot as it can cause additional stress on the material. The pattern and force of peening should be carefully controlled to ensure even distribution across the entire weld bead.

By introducing compressive forces into the material, peening counters internal stresses created during welding, resulting in stronger and more reliable welds.

What Does Peening do to Metal?

Peening is a powerful technique that can transform your metal into a stronger and more durable material.

Let’s explore what this process does to metal, and why it’s so essential in welding.

Peening involves striking a metal surface with a specialized peening hammer or other hard object to create a compressive stress layer.

This process is commonly used in welding to improve the strength and durability of the weld joint. During the cooling process of a weld bead, residual tensile stress can form in the metal, which can lead to cracking and failure over time.

However, peening helps counteract this tension by creating a compressive stress layer on the surface of the metal. The indentations created during peening cause the metal to expand and contract, which creates the desired compressive stress layer.

It’s like a workout for your metal – the indentations are like a personal trainer, strengthening and conditioning your metal to perform at its best. The benefits of peening are numerous and significant.

Firstly, it increases the strength and durability of the welded joint, making it less likely to fail over time. Secondly, it improves resistance to fatigue and stress corrosion cracking, which means you can be confident that your metal will last even longer.

And finally, peening can reduce distortion in the metal caused by welding, which results in a more aesthetically pleasing finished product. In conclusion, peening is not just a simple step in welding but an essential one that shouldn’t be overlooked.

Benefits of Peening a Surface

This powerful technique is like a personal trainer for your metal, enhancing its strength, durability, and appearance. Peening has numerous benefits, especially in the welding industry.

One of the most significant benefits is that it creates compressive stress on the weld bead’s surface. By doing so, it enhances the strength and durability of welded parts, reducing the chances of cracking or failure over time.

Peening is like a power-packed workout for your metal, making it stronger and more resilient. But that’s not all – peening also helps to improve the surface finish of the weld bead.

Just like smoothing out rough edges in a woodworking project, peening can smooth out any uneven surfaces caused by welding. This is especially important if the welded area is visible as it can enhance the overall appearance of the finished product.

It’s like giving your metal a makeover. In addition to improving strength and appearance, peening can also increase the fatigue life of welded parts.

By creating uniform stress distribution across the welded area, it reduces the risk of cracks or failures occurring over time. Peening is like a stamina-boosting exercise for your metal.

And let’s not forget about reducing distortion – another benefit of peening. By counteracting any tensile stress caused by welding, peening can prevent warping or distortion in the material.

It’s like a corrective exercise for your metal, ensuring that it stays in top form. Overall, peening is an essential process in welding that every welder should know about.

Vl1r-cseuEk” >

Conclusion

In conclusion, peening is a crucial post-welding process that involves striking the weld metal with a hammer or other materials like shot or glass beads.

This technique creates compressive residual stress, which significantly enhances the strength and durability of welding structures while reducing the possibility of fatigue failure. Peening also improves the aesthetic appeal of welding structures by creating a smoother surface for a polished look and reducing visible slag and spatter.

Think of peening as a spa day for your metal – it relieves stress and tension while refining its structure for optimal strength and toughness. By introducing compressive forces into the material, peening counters internal stresses created during welding, resulting in stronger and more reliable welds.

It helps counteract residual tensile stress that can form in the metal during cooling after welding. The benefits of peening are numerous and significant.

Overall, every welder should know about peening as it ensures the integrity and longevity of welding structures.