Ever wonder why pipeline welders wear those large, pancake-shaped hoods? It’s not just for show.

In this blog post, we’ll explore why they wear these unique pieces of protective gear and how they can shield welders from potential dangers associated with welding operations.

We’ll also look at the various types of materials that make up these hoods and why they’re so beneficial for safety.

So let’s jump in and discover the importance of pancake hoods for pipeline welders!

Benefits of Wearing a Pancake Welding Hood

Contents

- 1 Benefits of Wearing a Pancake Welding Hood

- 2 Are Pancake Welding Hoods OSHA Approved?

- 3 What Kind of Helmet Should You Wear for Pipeline Welding?

- 4 Why Do Pipeline Welders Wear Pancake Hoods?

- 5 Are Some Welding Helmets Flat?

- 6 Can You Wear a Hard Hat with a Pancake Welding Hood?

- 7 How to Choose the Right Pancake Welding Hood

- 8 Tips on Using a Pancake Welding Hood

Welding is an essential skill that requires proper safety precautions. Wearing a pancake welding hood is the perfect way to protect yourself from sparks and other debris that come with welding. Not only is it lightweight and comfortable, but it also allows for a wide range of vision, so you can see what you’re doing while you weld.

The hood is adjustable, allowing for a custom fit that ensures maximum comfort and safety. It is also OSHA-approved, giving you the assurance that it meets all the necessary requirements for protection. Plus, a sweatband helps keep your face dry during long hours of work.

A pancake welding hood offers both comfort and security when welding.

Are Pancake Welding Hoods OSHA Approved?

Pancake welding hoods provide superior protection compared to traditional helmets. Their flat lens design offers a larger viewing area with less distortion, so you can see more clearly when you’re working.

Plus, their wider shade number range (10–14) provides better shielding from UV radiation.

So if you want the best safety while welding, go with a pancake welding hood! It’s the smart choice for welders who want to stay safe on the job.

What Kind of Helmet Should You Wear for Pipeline Welding?

For pipeline welders, safety is of the utmost importance. The right helmet can protect you from the extreme heat and hazardous materials that come with welding in tight spaces. That’s why it’s essential to wear a pancake welding hood.

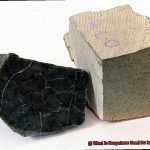

These helmets are made of an incredibly durable material that can withstand extreme temperatures. They offer more coverage than traditional helmets, making them perfect for welding in tight spaces or areas with hazardous materials.

Plus, they are OSHA-approved and meet safety standards for proper eye protection while welding.

The flat design of the pancake welding hood offers a clear view of the work area and fits comfortably on your head so you can see what you’re doing while welding.

The adjustable straps on the back make it easy to adjust for a comfortable fit and ensure that the helmet stays securely in place even during long periods of work.

Why Do Pipeline Welders Wear Pancake Hoods?

Pipeline welders need the ultimate protection when it comes to their safety equipment, and that’s why they often choose pancake hoods. These flat, circular helmets are designed to shield welders from sparks and slag while welding, providing superior protection compared to traditional welding helmets. Plus, they are OSHA approved, so welders can be sure they’re meeting safety standards.

For even more protection from debris, pancake hoods can be worn with hard hats.

This combination offers a great level of coverage for any pipe welder. On top of that, the flat shape of the hood gives the wearer a better field of vision than traditional helmets.

This increased visibility is essential for pipeline welders, who need to see as much of their work area as possible in order to do their job safely and efficiently.

In conclusion, pancake hoods provide essential protection and visibility for pipeline welders while they work.

Are Some Welding Helmets Flat?

You may be surprised to learn that some welding helmets are actually flat! Known as pancake welding hoods, these helmets offer several advantages over traditional models.

For starters, pancake welding hoods provide welders with an unobstructed view of their work, meaning they don’t have to wear a bulky and heavy helmet to get the job done. The flat design also allows for more air circulation, keeping welders cool during long hours of work.

In addition, pancake welding hoods are lighter and more comfortable than conventional helmets. They can be used in tight spaces where other types of helmets won’t fit, and they protect welders from sparks and other hazards associated with the job. Plus, they’re OSHA-compliant!

Can You Wear a Hard Hat with a Pancake Welding Hood?

Welding can be a hazardous activity, so it’s essential to make sure you’re wearing the right safety gear. A combination of a hard hat and a pancake welding hood is one of the most effective ways to protect your head and neck area from sparks and other debris.

The pancake welding hood fits securely over the top of the hard hat, providing an extra layer of protection. This combination is especially useful when welding in confined spaces or areas that contain dangerous materials.

It’s important to remember that wearing a hard hat with a pancake welding hood does not replace the need for additional safety equipment, such as gloves, protective clothing, and eye protection.

How to Choose the Right Pancake Welding Hood

Welding is a risky job, so it’s essential to make sure you have the right protective gear. A pancake welding hood is a must-have piece of safety equipment that will protect your face and eyes from sparks and heat. Here’s how to choose the right one for your needs:

Protection

The level of protection you need should also be taken into account. Pancake welding hoods offer varying levels of protection from basic to advanced, so choose one that meets your exact requirements.

Safety

Look for a helmet that is OSHA-approved and has been tested for performance and safety standards for your particular type of welding.

Fit

Comfort is key when it comes to safety gear, so make sure the helmet fits properly over your head and face. If it doesn’t fit correctly, it won’t provide adequate security in certain situations.

Features

To give you more control over your comfort and safety levels, look for adjustable features such as auto-darkening lenses and adjustable headbands. Additionally, consider any additional features such as an auto-darkening lens or a flip-up visor for better visibility.

Durability

Check the quality and durability of the materials used in construction to ensure they will last and provide adequate protection in the long run. Consider any replaceable parts or accessories that can enhance your experience with the hood as well.

Finally, make sure that you are familiar with all of the safety features of your welding helmet before beginning use. This will help ensure that you are properly protected when working with volatile substances in potentially lethal situations.

Tips on Using a Pancake Welding Hood

Welding is a dangerous job, and getting the right protective gear is essential for staying safe. A pancake welding hood provides crucial protection for your face and neck from sparks and debris during welding operations. Here are nine tips on how to use a pancake welding hood correctly and safely.

- Firstly, always wear protective clothing underneath the welding hood, such as long-sleeve shirts and pants, as well as gloves to protect your skin from sparks and heat. The welding hood should fit snugly against your head, with the front edge sitting just above your eyebrows. Additionally, ensure that the straps are fastened securely so that the hood does not slip off your head when you move around.

- Secondly, make sure the lenses are clean before you start welding. Any dirt or debris on the lenses could interfere with visibility or cause eye strain during welding operations. It’s also important to check your pancake welding hood regularly for any signs of damage, such as cracks, tears, or discoloration in the lens or other parts of the helmet. Replace worn-out parts, such as lenses and headgear, regularly to ensure maximum safety while welding.

- Thirdly, always wear safety glasses underneath your pancake welding hood for additional protection from sparks and debris during welding operations. Fourthly, make sure that the lens is clean and free of scratches to ensure optimal visibility while welding. Fifthly, replace your pancake welding hood when it gets worn out or damaged, as this can reduce visibility and protection while welding.

- Finally, clean your pancake welding hood after each use to keep it in good condition and ensure optimal performance during future uses.

- Conclusion

Pancake welding hoods are essential for pipeline welders, providing critical safety and visibility. Lightweight and convenient, these helmets meet all necessary safety standards to keep welders safe on the job.

With adjustable features such as auto-darkening lenses and adjustable headbands, they provide a secure fit that’s both comfortable and OSHA-compliant.

Combining it with a hard hat offers an extra layer of protection.