Do you have a beloved cast iron skillet that’s seen better days?

Maybe it’s sporting some unsightly cracks or chips, leaving you wondering if it’s time to retire it for good. Don’t give up on your cherished family heirloom or flea market find just yet.

There’s a cost-effective and efficient solution to restore your cast iron without welding. In this blog post, we’ll explore the various methods for fixing cast iron without welding.

From using JB Weld to repairing with a propane torch, we’ve got you covered. We’ll also share tips on how to properly maintain your cast iron, including the secrets of seasoning for long-lasting use.

Get ready to learn how to revive your favorite kitchen tool and cook up mouth-watering dishes in no time.

What is Cast Iron?

Contents

Cast iron is a remarkable alloy that has been utilized for centuries in diverse applications.

This durable material is made up of iron, carbon, and silicon, with additional elements such as manganese, sulfur, and phosphorus, which are added to enhance its properties. Cast iron is renowned for its exceptional heat retention and distribution, making it the preferred material for cooking utensils and stove parts.

Cast iron comes in various types, including grey iron, white iron, ductile iron, and malleable iron. Grey iron, the most common type, is recognized by its grayish hue and high carbon content.

White iron has lower carbon content and is harder and more brittle than grey iron. Ductile iron has a higher carbon content than grey iron but contains magnesium to make it more malleable or flexible.

Malleable iron is created by heat-treating white cast iron to eliminate its brittleness. This versatile material finds use in a wide range of applications, including construction, automotive parts, pipes and fittings, machinery components, and decorative items.

Due to its unique appearance and durability, cast iron remains a popular material for vintage and antique pieces. However, despite its resilience, cast iron can be prone to cracking or breaking under stress.

In the next section, we will explore some common reasons why cast iron can break and how to repair it without welding. When it comes to fixing cast iron without welding, there are several options available.

One popular method is using an epoxy adhesive such as JB Weld. This two-part epoxy can be mixed together and applied to the broken area of the cast iron.

Once it dries, it forms a strong bond that can withstand heat and pressure – think of it like super glue for metal. However, the strength of the bond will depend on the quality of the product and application technique.

It’s essential to sand or roughen the surface of the cast iron before applying the epoxy for better adhesion. Another option is using a metal-filled epoxy putty such as Devcon Titanium Putty.

This putty can be molded into shape and applied directly to the broken area of the cast iron. Once it sets, it forms a robust bond that can be sanded or machined to match the original shape of the cast iron.

For smaller cracks or chips on cast iron, super glue can also be used to bond them together.

Why You Should Fix Cast Iron Without Welding

Cast iron is a versatile and robust material used in various applications, from cooking pots to engine blocks.

However, it’s not impervious to damage, and one of the most common issues on cast iron is cracks and breaks. While welding has been the traditional way of fixing them, there are compelling reasons why you should consider fixing cast iron without welding.

Firstly, fixing cast iron without welding can be a more cost-effective option. Welding requires specialized equipment and training, which can be costly.

On the other hand, fixing cast iron with readily available materials such as epoxy or putty often only requires simple tools and materials. Secondly, fixing cast iron without welding can also save you time and effort.

Welding requires significant preparation time, including cleaning and preheating the metal surface. Conversely, using epoxy or putty to fix cast iron can be done quickly and easily.

Moreover, using epoxy or putty to fix cast iron can also be a more practical solution for specific types of repairs. For example, repairing small broken pieces or those located in hard-to-reach areas may be best fixed using epoxy or putty.

In conclusion, there are many benefits to fixing cast iron without welding. It can be a more cost-effective, faster, and practical option for certain types of repairs.

However, it is essential to choose the right adhesive for your specific repair needs to ensure a strong and long-lasting bond.

Using an Epoxy Adhesive to Repair Cast Iron

Cast iron is a durable and versatile material, but it is not immune to the occasional crack or break.

If you’re looking for a cost-effective and practical solution that doesn’t involve welding, using an epoxy adhesive to repair cast iron may be the answer you’ve been searching for. Epoxy adhesives are a powerful two-part solution made up of resin and hardener.

When mixed together, they create a reliable and sturdy bond that can fill gaps and provide excellent adhesion to metals like cast iron. However, before you start your repair project, ensure that you have the right epoxy adhesive for the job.

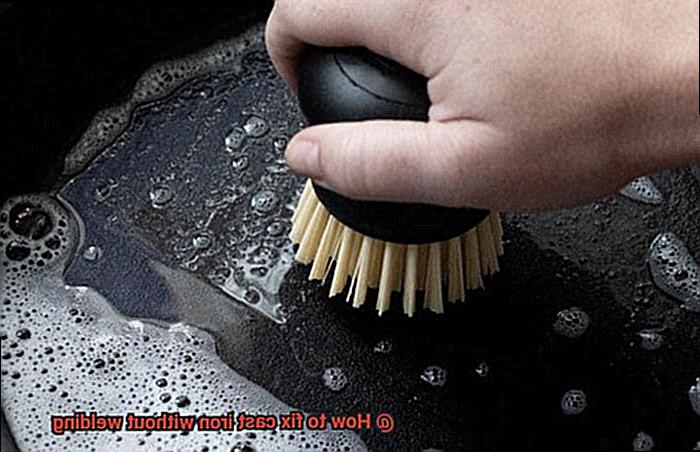

To begin, thoroughly clean the surface of the cast iron. Use a wire brush or sandpaper to remove any rust, dirt, or debris.

Once the surface is clean, wipe it down with a clean cloth to remove any remaining dust or debris. Next, mix the two parts of the epoxy adhesive according to the manufacturer’s instructions.

Apply the mixed adhesive to the area to be repaired, making sure to fill any gaps or cracks entirely. Use a putty knife or spatula to smooth out the surface and remove any excess adhesive.

It’s crucial to allow enough time for the adhesive to cure completely before using the repaired item. The curing time may vary depending on the type of epoxy used and environmental conditions such as temperature and humidity.

Therefore, it’s best to follow the manufacturer’s instructions carefully for curing time. When selecting an epoxy adhesive for repairing cast iron, ensure that it is specifically designed for metal bonding and recommended for use on cast iron.

Not all epoxy adhesives are created equal, so research your options before making a purchase. In conclusion, using an epoxy adhesive is an effective way to repair cast iron without welding.

Remember to choose an epoxy adhesive specifically designed for metal bonding, follow the manufacturer’s instructions carefully, and allow plenty of time for curing.

Using a Metal-Filled Epoxy Putty to Repair Cast Iron

Cast iron is a timeless material that is utilized in a variety of household items, from antique furniture to cookware and machinery.

However, even the strongest materials can suffer from cracks or breaks over time. Fortunately, using a metal-filled epoxy putty is a simple and cost-effective solution to repair cast iron without welding.

The process of using a metal-filled epoxy putty is straightforward but requires some attention to detail for optimal results. The first step is to thoroughly clean the surface of the broken area.

Think of it like preparing a canvas for painting – you want a clean and smooth surface to work with. Next, mix the two parts of the epoxy putty together until they are fully blended.

It’s like mixing ingredients for your favorite dish – you want everything well combined for the best outcome. Then, apply the putty to the broken area and shape it as needed to fill any gaps or cracks.

It’s like sculpting with clay – you want to mold it into the desired shape for a smooth finish. After applying the putty, it’s crucial to give it enough time to cure and harden completely.

Curing time can vary depending on the brand and type of epoxy putty used, but typically it takes around 24 hours. Think of it like letting cookies cool down after baking – you want to give them enough time to set before enjoying them.

Once the putty has fully cured, you can sand it down, drill into it, and even paint over it for a seamless finish. It’s like adding finishing touches to a masterpiece – you want to make sure everything looks perfect.

Using a metal-filled epoxy putty provides a strong and long-lasting bond for small cracks or breaks in cast iron. However, keep in mind that larger repairs or areas under high stress or pressure may not be suitable for this method.

With proper preparation and care, though, using a metal-filled epoxy putty can be an effective way to extend the life of your cast iron items without breaking the bank on welding services.

So, repairing cast iron with a metal-filled epoxy putty is an easy and practical solution that anyone can do at home.

Using Super Glue to Bond Small Cracks in Cast Iron

This quick and easy solution is perfect for minor repairs, though it’s important to note that it isn’t suitable for larger cracks or breaks. Super glue, also known as cyanoacrylate adhesive, works by bonding the surface of the crack together.

This creates a strong and durable bond that will keep your cast iron item functional and beautiful. But before you start gluing, make sure to clean the area around the crack with a wire brush or sandpaper.

This will help ensure that the surface is free of any dirt or debris that could interfere with the bonding process. Once you’ve prepped the area, apply a small amount of super glue to the crack.

Spread it evenly over the surface, making sure to hold the two sides of the crack together for a few minutes until the glue sets. Voila.

Your cast iron item is good as new. It’s important to note that while super glue can be effective in bonding small cracks in cast iron, it’s not a permanent solution.

Over time, the bond may weaken and the crack may reappear. For more serious repairs, it’s recommended to seek professional help or consider other methods such as welding or brazing.

Before using super glue on cast iron, make sure that the type of super glue being used is suitable for metal bonding. Not all types are strong enough to bond cast iron and may result in a weak or unstable repair.

Just remember to assess the severity of the damage and seek professional help if necessary for larger repairs.

Choosing the Right Method for Your Repair

When it comes to repairing cast iron, choosing the right method is key to ensuring a successful and long-lasting repair.

With several methods available, each with its own advantages and disadvantages, it can be overwhelming to decide which one is best suited for your needs. But fear not.

We’re here to help you make an informed decision. Let’s start with epoxy or adhesive.

This is a popular method for small repairs or cracks in cast iron. Think of it as using a glue stick – easy to use and can provide a strong bond.

However, keep in mind that it may not be suitable for larger repairs or areas that require high strength. So, if you’re dealing with a heavy-duty repair, this may not be the right method for you.

Next up is brazing. This method involves melting a filler material into the broken area, providing a strong bond that’s perfect for repairs that require high strength – such as engine blocks or heavy machinery parts.

However, it does require more skill and equipment than epoxy or adhesive. It’s like using a blowtorch – effective, but only if you know what you’re doing.

Finally, we have welding. While it’s often recommended for larger repairs or areas that require high strength, welding can be challenging due to the brittle nature of cast iron.

It requires specialized equipment and a high level of skill – similar to using a power tool. If you’re not confident in your skills, you may want to consider other options.

Factors such as strength, location, and skill level should all be taken into consideration when selecting the right method for your cast iron item.

RvdD9RvbAzI” >

Conclusion

In conclusion, fixing cast iron without welding is a smart and budget-friendly way to mend cracks and breaks in your beloved cast iron objects.

You can opt for an epoxy adhesive, metal-filled epoxy putty, or super glue depending on the extent of the damage. It’s crucial to pick the right method for your repair needs based on factors like location, strength, and expertise level.

Welding may be ideal for larger repairs or high-stress areas, but it can be tricky due to cast iron’s brittle nature. Alternatively, using an epoxy adhesive or metal-filled epoxy putty could be a quicker and more practical solution for specific types of fixes.

Before applying any repair method, make sure you clean and prep the surface thoroughly and follow the manufacturer’s instructions diligently for optimal outcomes.