Pinch welding is a procedure used for joining wheels and tires to a vehicle’s chassis.

Pinch welding is a less efficient method of fabricating car fixtures, but it’s much more cost-effective — leaving us with either a cheaper or better result regardless of who uses it.

What is a Pinch Weld?

Contents

Traditionally, pinch-welding has been utilized by the automotive industries.

Pinch-welding is also commonly used in industries that manufacture heavy fabrications. Pinch-welding is an efficient method of welding that yields good results.

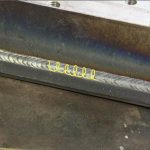

A pinch weld is considered an easily identifiable weld that has been formed by the flow lines of one layer of metal joining with another layer.

Seam welding in which the molten metal from one layer flows over and connects with the lower layer is known as a pinch weld.

A pinch weld is made when two pieces of metal are pressed together. This causes the molten metal to flow from the lower layer into the top layer.

Pinch welds are typically used on thin sheets or sheet-metal components.

As a result, the weld does not need to penetrate the sheet and is typically limited to much smaller areas.

Due to the short length of the weld, welding rods are most often used for this process. Pinch-welding is cheaper than other forms of welding, and it can also be applied to complex areas that are difficult to reach.

Z – Shaped

Z-shaped pinch welds are the preferred method of lifting automobiles.

A urethane bead is on one l-shape, and a metal sheet is in the opposing L-shape.

The urethane bead is characterized by a cone-shaped indentation that allows it to pinch the metal. The metal sheets are kept in place by screws.

Car windows and windscreens act as barriers, protecting the car’s occupants from objects and animals such as animals and insects.

Protecting the top of the automobile is just as crucial as protecting the bottom.

The bottom, on the other hand, is vulnerable to pinches . It is more likely to pinch because the elevation point and the metal pinch weld are closer.

This is due to the fact that z-shaped pinch welds can be lethal when attempting to lift a vehicle.

Before using one, be sure you’ve done all necessary inspections to the car.

Be sure it is properly elevated, and that the jack and the jack stands are sturdy and capable of supporting the weight of the car. Once the vehicle has been inspected, the pinch weld can be used.

Once the two pinch welds are joined, the slope can be used to lift the vehicle.

L – Shaped

Many automobiles have the L-shaped weld running along the bottom.

That which runs along the side of the vehicle is nicknamed the “L,” and the part underneath is called the “V.” L-shaped pinch welds are made using a mig welder and stainless steel sheets.

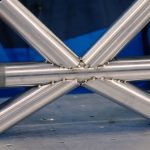

In order to weld two sheets together, they must first be placed parallel to each other so that the bend in the L-shaped sheet matches the angle of the flat sheet. Then, the entire assembly is welded together.

There must be a 90-degree bend in one sheet, and the L-shaped weld must mate with flat sheet metal on the opposite sheet.

Spot welding must be used to attach several other parts to one another as well, including the fenders to the doors, the gas tank to the frame, and so on.

As a last step, run a piece of wire or two across the adhesive to join it securely to the sheet.

Due to the use of this method, almost all automobile manufacturers have adopted it, and it is now a staple part of the production process.

Flat Shaped Pinch Welds

It’s common for novice welders to find pinch welds to be the most difficult.

This is because first-timers can have a hard time maneuvering the two pieces of metal together. Additionally, pinch welds don’t offer a great deal of protection, so it’s important to have a clear understanding of where pinch welds are used.

Welders employ a unique process to create these joints. It’s called pinch welding, and it’s most commonly used on tubular pieces. Pinch welding on tubular pieces is also very demanding, but it’s worth it.

To create this junction, welders fuse two pieces of metal.

The metal powder particles fuse together to create a stronger, more stable connection between the two parts of the car. The shape of the weld depends on the style of vehicle that it’s used for.

Pinch welds are used in a common type of car frame, which is called a front-to-rear frame. This means that the front part sits across the rear part.

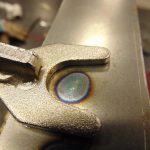

To attach the two metal pieces together, you pinch them between a pair of pliers.

The reason for this is that a filler material needs to be added to the weld. The filler material is then melted by the heat of the arc.

Use this weld to protect moving parts from corrosion.

How Do You Jack On A Pinch Weld?

Off-roading is something you’re passionate about, and it’s important to develop a safety culture that will ensure that your experience remains as enjoyable as possible.

Using the proper tools, procedures, and safety considerations is essential to avoid injury.

You can jack up your car using a lift. A lift allows you to safely lift your vehicle off the ground so you can work on it.

Before you jack up your car, you need to remove your car’s wheels. You can use a jack stand to do this.

Jack stands allow you to control how much support your chassis receives. They are designed to be sturdy enough to support the weight of your vehicle.

You also need a jack. A jack is a long metal rod that allows you to lift your vehicle off the ground.

The Rennstand by Safe Jack

The Rennstand is versatile as well.

It may be adjusted to many different heights so that it can be used with a wide range of cars. It even comes with safety cables to ensure that the jack stand doesn’t fall over and cause damage.

It has replaceable jack pads that you may need with different cars.

The pads are made out of silicone rubber, which grips the car while it’s on the stand, so it won’t slip. The Rennstand has four jack pads and the pads can be adjusted to accommodate different car sizes.

In order to protect the car’s paint, the pads can be covered with fine sanding paper.

The Rennstand is made out of galvanized pipe that is coated to prevent rust. It is made of a strong material, making it very durable.

Use the Correct Jack

Jacking points are designed to be used alongside welding attachments, such as lift and spreader plates, for example.

However, if you use the improper jack or the wrong jack pad, you risk damaging the side of the vehicle, as well as the frame of the vehicle.

Instead, make use of a jack pad in order to distribute the vehicle’s weight across the entire weld.

Using a pad, the vehicle’s wheel will be optimally supported by two jack points. This will help prevent the vehicle from moving during the weld process.

You may prevent weakening the welds by making sure that you carefully select the right jack for the job.

We also recommend that you avoid utilizing aftermarket jack stands whenever possible. They are convenient, but they aren’t always the safest way to handle your vehicle.

You should only use them if your vehicle’s original jack pads are damaged, or if you feel the need to make heavy adjustments.

Change the Jack Stand Points

First, make sure that the vehicle’s bumper is clean and free of any scratches and dirt.

Then, use a welding machine to weld the tip of the jack stand to the pinch weld. Follow the manufacturer’s instructions to ensure the best results.

Use the pinch welds between the frame and the sheet metal to make the vehicle sturdier.

Lifting a big automobile is made easier by attaching pinch welds to the vehicle’s structure.

Pinch welds allow the maker of the car to attach the car’s interior body to the front end of the frame easily, without drilling holes in the vehicle’s outer bodywork.

For added security, transfer your vehicle to the jack stands after it has been safely lowered onto the jack.

Use A Jack Pad

Generally, pinch welds are used in areas on the vehicle that are prone to bending.

In order to avoid permanent and irreversible damage to the metal body panels, you should use a jack pad or a sheet of plywood under the vehicle.

Stress causes the metal panels of the car’s body to stretch and bend, causing cracks in the paint on the surface and weakening the structural integrity of the panels.

To ensure the safety of vehicle passengers, pinch welds are designed to provide maximum support. The auto-body repair industry uses hydraulic jack pads to jack the car up around pinch welds.

These pads are specially designed to withstand the heavy weight and pressure exerted by hydraulic jacks.

Also Read: Can You Mig Weld Brass To Steel?

Conclusion

When it comes to the pinch weld, you’re definitely going to want to keep it shiny and clean.

The part is made from aluminum, which is fairly soft metal. This means that it’s prone to corrosion.

This is one of the main reasons why it’s necessary to maintain it. To ensure it stays in the best possible condition, you should regularly clean it using a piece of soft or cotton cloth.

Some shops that sell car parts also offer a special service that will properly maintain the weld for you.

In addition to providing structural support for the body panels, the pinch weld also keeps the door and hood shut.

Without them, it’s only a matter of time before the panels start to fall apart.

Your automobile would be little more than an expensive paperweight without it.

The information in this article has given you a good idea of how pinch welds work.