If you’re a skilled welder looking for an edge, this course is for you.

You’ll learn how powerful and effective MIG welding can be for a range of metalwork, from welding car engines to repairing tractor parts.

Learn how to customize your welds for strength, how to properly weld automobile panels, and what to expect from welding MIG welds.

You’ll learn the ins and outs of MIG welding, from how to properly choose and use welding equipment and tools, to how to weld, test, and inspect for strength and stability.

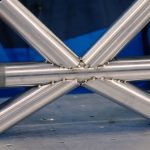

How Strong Is A MIG Weld?

Contents

To directly address your question, a MIG weld is stronger than the parent material, because the filler metal is fused with the parent material.

Exceeding the 70,000 PSI minimum percentage in a MIG weld, however, will not cause it to fail. Instead, it will be stronger than the parent material.

How to Make Strong MIG Welds

If you’re new to MIG welding, take the time to learn each part of the process.

MIG welders always use gas tungsten arc welding (GTAW) equipment. The arc is a spot welder that uses a tungsten electrode.

The electrode moves back and forth. The electrode is a wire whose ends are coated with molybdenum flux and welded together.

The flux coating gives it the ability to produce a high amount of heat, which helps melt the metals being welded. MIG welder s are typically trained to stick weld.

You can make your MIG weld stronger by controlling the speed of the weld, how much voltage you are applying, and the depth of penetration.

If the weld is too fast, the filler metal will not be able to reach the weld pool. An MIG weld that is too deep will not melt properly, and you won’t be able to get a strong weld.

Aside from practice, there are a few key things to consider.

First of all, you should consider the type of wire you are using. Using the right wire will make a noticeable difference in the strength of your MIG weld.

If the wire is too thin, the weld will be weak. If the wire is too stiff, however, it will be difficult for it to flow properly.

In order to find the right wire for your task, it is a good idea to consult with a professional.

Modify settings as you work

To prevent burn through, establish your welding parameters beforehand.

You can fine-tune controls until you achieve the exact settings because every metal is different.

I know it seems hard, but with some practice, you’ll know exactly what settings to use and how to fine-tune.

It’s critical to use the correct settings each time you weld.

If you’re just starting out, weld with a 2.5 amp wire feed, 20 amps, and 2,000 watts. These settings are a good starting point for welding thin metals.

As you gain more experience, you can adjust the settings to verify your welds and create stronger welds.

However, the voltage and wire feed speed must vary in order to prevent overheating the weld.

Shorten the wire.

An unpredictable arc is caused when the wire doesn’t reach the tip of the magnet.

When MIG welding uphill, it’s important to have a very steady control. The longer the wire is, the higher your arc will be.

This would most likely affect the quality of your weld.

However, if you watch your arc carefully, you should be able to control it on the shorter stick. A shorter stick will also make it easier to judge your weld on the longer part of the weld.

It will improve the quality of weld that you make.

The quality of the solder joint will determine how long you can last with your copper pipe.

This is the one I’m currently using and it works great.

Two passes along the weld joint are required.

Taking an additional pass will reduce the size of the puddle.

Running two passes is a wonderful, cost-effective, and easy way to keep a strong MIG weld.

A second weld is also stronger if the first wasn’t too hot.

A little pre-heating is ideal if it’s winter.

Make careful it you do not over heat the weld and melt the filler metal.

Make sure your welds are up to par by practicing and testing them.

You need to know whether the procedures and tools you use can produce a good weld. It’s better to make several practice welds than to have one fail when you go to weld the actual part.

Make a practice weld and apply some pressure. If the weld doesn’t crack, you’re ready for the next step.

On a welded section, you may apply enough pressure to pop the weld.

You should adjust your approach and welding settings for tougher welds, which require more force to get the job done.

Remove impurities

If the metal is not clean, the weld will be weak or brittle.

The weld is the strongest part of the weldment. As a result, it is important to ensure that the weld is the strongest part of the weldment.

Because GMAW welding is a very sensitive technology, it is normally recommended that you use at least two different electrodes per weld.

The electrodes for GMAW welding use aluminum and lead oxide to create an arc that melts your aluminum filler material.

GMAW welding is a process that can create welds that are significantly stronger than those that are made using other techniques.

However, the strength of the GMAW weld will depend on the type of metal and any impurities that are in the piece you are welding.

As a result, make sure your metal has minimal porosity in order to maximize the strength of the weld.

Also Read: Can You Mig Weld Brass To Steel?

Conclusion

As you can see, there are truly unlimited possibilities with this welding procedure. MIG welding can bypass problematic areas, such as the joints between damaged pieces of metal.

It’s a good option if you have the technical skills necessary to apply it.

MIG welding requires certain safety precautions and practices, which can vary based on the MIG machine being used.

Depending on the type of MIG machine you are using, there may be different requirements as far as your skill level, knowledge, and type of weld.

There are MIG welding machine types that are suitable for beginners and others that may require more technical skills.

Deep penetration and strong welds may be achieved by using MIG welding in a number of methods.

We’ve covered a large range of material, from additional welding tips to detailed instruction about MIG welding setups.