Stainless steel is a versatile material that is widely used in both industrial and domestic settings due to its impressive resistance to corrosion and high heat.

However, cutting stainless steel can be a daunting task, especially if you lack the proper tools. Thankfully, plasma cutters are an excellent option for cutting through stainless steel with ease.

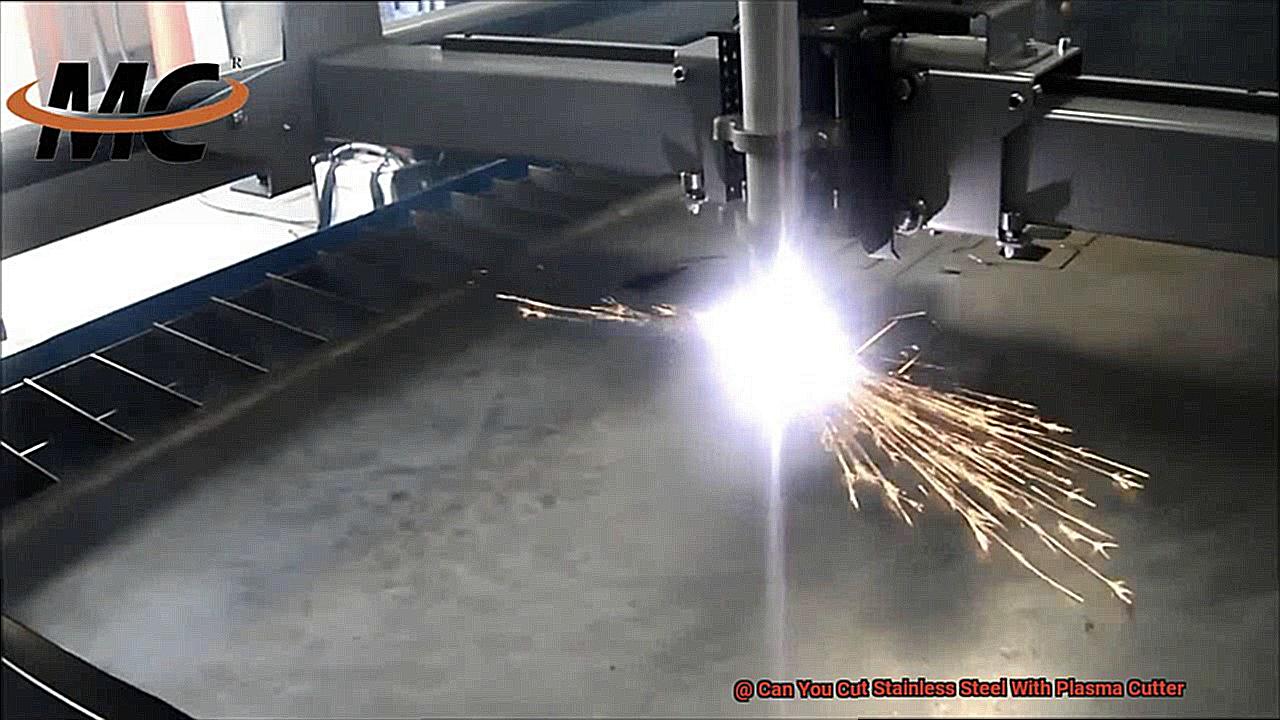

So, can you cut stainless steel with a plasma cutter? Absolutely.

Plasma cutters are highly capable of slicing through this durable metal, making them a popular choice among professionals and DIY enthusiasts alike. However, there are several crucial considerations to keep in mind when using a plasma cutter to ensure optimal results.

In this article, we’ll delve into the question “Can You Cut Stainless Steel With Plasma Cutter” and explore key factors that can affect the quality and accuracy of your cuts. We’ll examine variables such as the thickness of the steel, the type of plasma cutter you use, and its settings.

Additionally, we’ll share some valuable tips and tricks that will help streamline your cutting process. Whether you’re a seasoned professional or just starting with DIY projects, our guide will provide helpful insights into the advantages and disadvantages of using a plasma cutter for cutting stainless steel.

So why not join us on this exciting journey as we explore the power of plasma cutters in tackling even the toughest stainless steel cutting tasks?

What is a Plasma Cutter?

Contents

- 1 What is a Plasma Cutter?

- 2 Can You Cut Stainless Steel With a Plasma Cutter?

- 3 Considerations Before Using a Plasma Cutter on Stainless Steel

- 4 Types of Gas Used for Cutting Stainless Steel

- 5 Consumables Needed for Cutting Stainless Steel

- 6 Benefits of Using a Plasma Cutter on Stainless Steel

- 7 Conclusion

If you’re looking for a tool that can cut through tough metals like stainless steel with ease, look no further than the plasma cutter.

This powerful tool uses a high-velocity jet of ionized gas, known as plasma, to make precise cuts through metal. So, how does it work?

The process starts with an electric arc between an electrode and the metal being cut. This creates plasma, which is a highly ionized gas that produces extreme heat to melt the metal as it passes through it.

The result is a clean and precise cut that’s sure to impress. The plasma cutter consists of several main components, including a power supply, gas inlet, nozzle, and electrode.

The power supply provides the electrical charge needed to ionize the gas, while the gas inlet supplies the gas that creates the plasma. The nozzle directs the plasma towards the metal being cut, while the electrode maintains a safe distance from the metal.

Now, what about the different types of plasma cutters available? There are two main types: handheld and mechanized.

Handheld plasma cutters are portable and typically used for smaller jobs or on-site work. On the other hand, mechanized plasma cutters are larger and more powerful and are ideal for industrial applications or large-scale metal fabrication.

When cutting stainless steel with a plasma cutter, there are a few things to keep in mind. First, make sure you have the right type of plasma cutter with a high amperage output designed specifically for cutting thick materials like stainless steel.

Second, use the right type of gas – an argon/hydrogen mixture is recommended for cutting stainless steel. Finally, make sure you have the right consumables made from materials like tungsten or hafnium to ensure a clean and precise cut.

In conclusion, a plasma cutter is a versatile tool that can be used to cut through various types of metals, including tough stainless steel. With its ability to generate precise cuts quickly and efficiently, it has become an essential tool in many industries that rely on metal fabrication.

Can You Cut Stainless Steel With a Plasma Cutter?

With its high-velocity jet of ionized gas, cutting through this tough material has never been easier. But before you get started, there are a few key factors to consider.

First and foremost, it’s essential to ensure that your plasma cutter is designed to handle stainless steel cutting. Not all plasma cutters are created equal, so be sure to double-check the manufacturer’s specifications before firing up your plasma cutter.

Once you have confirmed that your plasma cutter is up to the task, it’s time to optimize your cutting conditions. The quality of your cut will depend on several factors, such as the thickness of the stainless steel, the type of gas being used, and the amount of power supplied to the cutter.

By carefully adjusting these variables, you can achieve clean and precise cuts that are sure to impress. But let’s not forget about safety.

When working with a plasma cutter, it’s crucial to wear protective gear such as welding helmets, gloves, and clothing to prevent burns or other injuries. Proper ventilation and eye protection are also necessary to prevent exposure to fumes and harmful radiation.

Considerations Before Using a Plasma Cutter on Stainless Steel

Before you get started, it’s important to consider a few key factors that can make or break your project.

But don’t worry, I’m here to guide you through the process and help you achieve excellent results. The first thing to keep in mind is that not all plasma cutters are created equal.

Different metals require different types of cutters, so it’s crucial to select the appropriate one for your project. Using the wrong cutter can lead to substandard cuts and damage to your material.

Think of it like trying to use a screwdriver instead of a hammer – it might work in a pinch, but it won’t give you the best results. Another important consideration is the thickness of your stainless steel.

Plasma cutters have their limits, so you need to make sure your cutter is capable of handling the thickness of your material. Check the manufacturer’s specifications before you begin cutting to avoid damaging your equipment or creating poor-quality cuts.

Safety should always be a top priority when working with high-temperature tools like plasma cutters. Sparks and spatter generated during cutting can pose a fire hazard, so it’s essential to wear proper protective gear such as welding gloves, goggles, and clothing.

Keep a fire extinguisher nearby just in case. Before you get started with your plasma cutter, take some time to prepare your stainless steel properly.

Any contaminants such as rust or oil can affect the quality of your cuts, so ensure that your material is free of these substances beforehand. Marking out your cut line with a straight edge or template can also help you achieve accuracy and precision.

In summary, cutting stainless steel with a plasma cutter can be a breeze if you keep these considerations in mind. Choose the right cutter, check its specs, take safety precautions, and prepare your material properly for best results.

Types of Gas Used for Cutting Stainless Steel

Cutting stainless steel with a plasma cutter is a delicate art, and choosing the right gas is crucial to achieve the perfect cut.

Each gas option has its own unique characteristics that impact the quality of the cut. Compressed air is the go-to for most projects due to its affordability and availability.

It’s a reliable option, but it can leave behind more dross and slag than other gases, resulting in a rougher cut. Nitrogen is another popular choice for plasma cutting stainless steel.

It produces a cleaner cut compared to compressed air, with significantly less dross and slag left behind. However, nitrogen comes at a higher cost and requires higher gas flow rates.

Oxygen is another option for achieving a clean cut on stainless steel. Using oxygen results in an exceptionally clean cut with minimal dross and slag.

However, it comes with a higher price tag due to the need for higher gas flow rates. For those who want the ultimate precision in their cuts, argon-hydrogen is the way to go.

This exclusive gas mixture produces an exceptional cut quality, free of any dross or slag. However, it’s also the priciest option and requires specialized equipment to use.

Choosing the right gas for cutting stainless steel with a plasma cutter depends on various factors such as cost, quality of cut required, and availability of gases.

While compressed air is the most commonly used option due to its affordability and accessibility, other gases such as nitrogen, oxygen, and argon-hydrogen can also be used depending on the specific needs of the project.

Consumables Needed for Cutting Stainless Steel

Cutting stainless steel with a plasma cutter is an art form that requires skill, precision, and the right tools.

Without the proper consumables, achieving clean and precise cuts can be like trying to sculpt with a dull chisel. The consumables necessary for cutting stainless steel include the electrode, nozzle, and swirl ring.

Each of these tools has a specific purpose in achieving the desired result, similar to how a painter carefully selects their brushes. The electrode is like the conductor of an orchestra – it creates the electric arc that heats and melts the metal.

When cutting stainless steel, it’s crucial to use an electrode with a slightly larger diameter than when cutting other metals. This prevents overheating and breakdown during the cutting process.

The nozzle is like the fine-tipped brush used for painting intricate details – it directs the flow of plasma onto the metal and controls the size of the cut. For cutting stainless steel, it’s important to use a nozzle with a smaller orifice size than when cutting other metals.

This allows for more concentrated heat, resulting in cleaner and more efficient cuts. Finally, the swirl ring is like the blender used by a master chef – it creates a swirling motion in the gas flow that stabilizes the plasma arc and improves cut quality.

For cutting stainless steel, using a swirl ring specifically designed for this purpose is vital to ensure stability and precision in your cuts. In summary, having the right consumables is fundamental to cutting stainless steel with a plasma cutter.

Benefits of Using a Plasma Cutter on Stainless Steel

Cutting through stainless steel can be a daunting task, but with the help of a plasma cutter, it’s a breeze.

This mighty tool offers precision, speed, and efficiency, making it an essential part of any welder or fabricator’s inventory. Here are some of the top benefits of using a plasma cutter on this notoriously tough material.

Firstly, plasma cutters are fast and efficient. They slice through stainless steel like butter, allowing for precise cuts in record time.

It’s like having a high-speed train that can take you to your destination without any delays, enabling you to finish your projects quickly and accurately. Another major advantage of plasma cutting is that it produces clean and smooth cuts.

Unlike other methods that create rough edges or heat-affected zones, plasma cutting reduces the risk of warping or distortion in the material. It’s like having a magic wand that can transform your workpiece into a masterpiece with ease.

Plasma cutters are also versatile and can handle various thicknesses of stainless steel. This makes them ideal for use in a range of industries, from automotive and construction to manufacturing and fabrication.

With this tool, you can tackle any project that comes your way, no matter how challenging. Moreover, plasma cutters are relatively easy to use and require minimal setup time.

They also produce less noise and dust compared to other cutting methods, making them a safer and more environmentally friendly option. It’s like having a trusty sidekick that works tirelessly by your side, helping you accomplish your goals with ease.

QDD4X21XR8g” >

Conclusion

In summary, cutting stainless steel with a plasma cutter is not only feasible but also efficient and precise.

Plasma cutters are capable of slicing through even the most robust materials like stainless steel due to their ability to generate high-velocity ionized gas. However, before using a plasma cutter on stainless steel, there are several crucial considerations to keep in mind.

Firstly, it’s essential to have the right type of plasma cutter with high amperage output designed specifically for cutting thick materials like stainless steel. Secondly, selecting the appropriate gas and consumables is vital in achieving clean and precise cuts.

Lastly, safety should always be a top priority when working with high-temperature tools like plasma cutters. Despite these considerations, using a plasma cutter on stainless steel offers numerous benefits such as speed, efficiency, versatility, and precision.

It’s an excellent tool for professionals and DIY enthusiasts who want to achieve accurate and clean cuts quickly and efficiently. So why struggle with outdated cutting tools when you can upgrade to a plasma cutter today?

With this tool by your side, you can tackle any project that comes your way with ease and confidence.