Are you someone who loves to tinker around in your workshop with a plasma cutter?

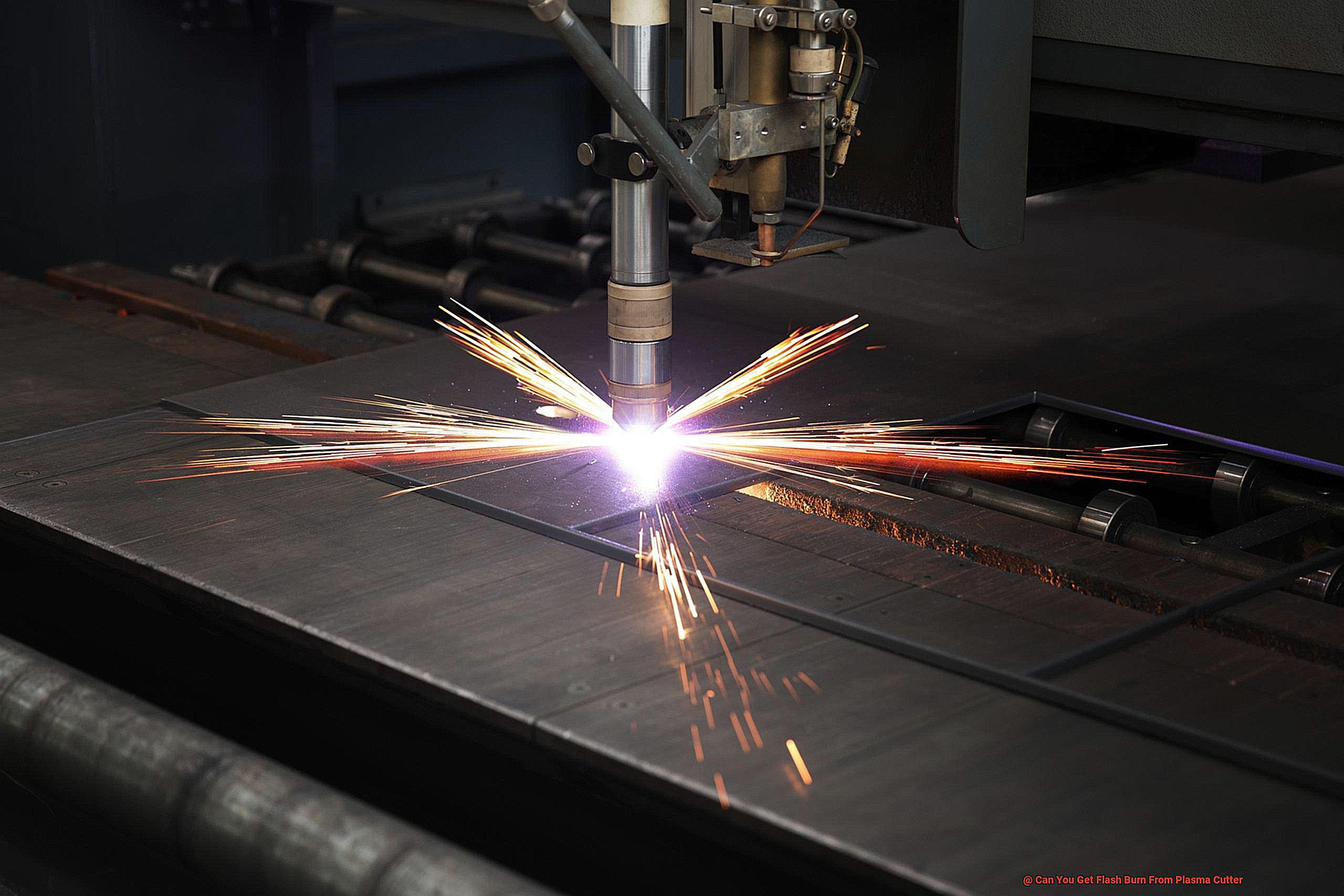

Or perhaps you’re a professional welder who uses this tool on a regular basis. While plasma cutters are fantastic for achieving precise cuts on various materials, they can also pose potential hazards if proper precautions aren’t taken.

One of the most significant risks associated with these tools is flash burn. So what exactly is flash burn?

It’s an excruciatingly painful burn that occurs on your skin or eyes due to exposure to high-intensity ultraviolet (UV) radiation from the plasma arc. This type of injury can leave you incapacitated for days, causing swelling and redness that make it impossible to work.

To avoid such a calamity, it’s crucial to understand the safety protocols involved in using a plasma cutter – particularly when it comes to preventing flash burns. In this blog post, we’ll explore one of the most common questions asked by plasma cutter users worldwide: Can You Get Flash Burn From Plasma Cutter?

So, keep reading.

What is Flash Burn?

Contents

Flash burn is a painful condition that can leave you feeling like you’ve stared directly at the sun for too long.

It’s caused by exposure to intense ultraviolet (UV) light, which is emitted during welding or plasma cutting operations. This condition, sometimes referred to as arc eye or welder’s flash, can lead to temporary inflammation of the cornea, the clear outer layer of the eye.

Symptoms include redness, pain, and sensitivity to light. In some cases, flash burn can even result in a loss of vision or color perception, making it a serious problem.

The symptoms of flash burn usually appear several hours after exposure to UV light and can last for several days. Seeking medical attention immediately after experiencing these symptoms is crucial.

Treatment for flash burn typically involves resting the eyes and using eye drops to reduce inflammation and pain. In severe cases, prescription medication may be necessary.

It’s important to understand that anyone who works with welding tools that produce high levels of UV radiation is at risk of experiencing flash burn. This condition can occur when protective eyewear is inadequate or not worn at all, making it essential to take proper safety precautions when working with these tools.

Investing in protective gear such as welding helmets or goggles can significantly reduce the risk of flash burn. Additionally, covering your skin with protective clothing and working in a well-ventilated area are other ways to minimize exposure to harmful fumes and gases.

Sources of Flash Burn

First off, let’s talk about what causes flash burn.

This painful condition is primarily caused by exposure to intense ultraviolet (UV) radiation emitted during welding or plasma cutting. The intensity of this radiation depends on various factors such as the type of equipment being used, the distance between the equipment and the operator, and the duration of exposure.

Additionally, reflected light can increase the risk of flash burn, especially if you’re not wearing proper protective equipment. While UV radiation and reflected light are the most common sources of flash burn, other factors can also contribute to this painful condition.

For instance, working in confined spaces with poor ventilation can trap the radiation and make it more intense. Using poorly maintained or calibrated equipment can also increase your risk of flash burn.

And if you’re working in an environment with other sources of UV radiation – such as direct sunlight – your risk may be even higher. But fear not.

There are plenty of ways to protect yourself from flash burn. The most important thing you can do is wear appropriate personal protective equipment (PPE).

This includes a welding helmet with a shaded lens to protect your eyes, gloves to shield your hands, and clothing made from flame-resistant materials to safeguard your skin. Additionally, it’s essential to work in a well-ventilated area to minimize exposure to concentrated radiation.

And if you can avoid working in direct sunlight, even better. Finally, don’t forget about proper maintenance and calibration of your welding or plasma cutting equipment.

By keeping your gear in tip-top shape, you can minimize your risk of excessive UV radiation exposure and prevent flash burn. In conclusion, flash burn is a serious condition that is caused by exposure to intense UV radiation during welding or plasma cutting.

However, by understanding the sources of flash burn and taking appropriate precautions, you can protect yourself from this painful condition and enjoy a safer, more productive working environment.

Risk Factors of Flash Burn from Plasma Cutter

Plasma cutting produces intense light that can damage the cornea and cause temporary or permanent vision loss. To safeguard against this, welders must wear proper eye protection such as welding goggles to shield their eyes from the bright light.

Working in poorly ventilated areas is another risk factor for flash burns. Plasma cutting generates fumes and gases that can be harmful if inhaled.

These fumes can cause respiratory problems and impair lung function. So, it is critical to work in well-ventilated areas or use respiratory protective equipment to prevent inhalation of these hazardous substances.

The distance between the plasma cutter and the workpiece can also be a risk factor. If the torch is too close to the workpiece, it can produce intense heat that can cause flash burns.

To avoid this, welders must maintain a safe distance between the torch and the workpiece. Using damaged or worn-out equipment is another significant risk factor for flash burns.

Malfunctioning equipment may produce unpredictable results, causing accidents and injuries. Therefore, welders should always inspect their equipment before use and replace any worn-out or damaged parts.

Lack of training and experience is another critical risk factor for flash burns from a plasma cutter. Welders should receive adequate training on how to use plasma cutters safely and effectively.

They should also have experience using plasma cutters before attempting any complex or intricate projects. In conclusion, understanding the risk factors associated with flash burns from a plasma cutter is crucial for welders’ safety and well-being.

Signs and Symptoms of Flash Burn

Experiencing a flash burn from a plasma cutter can be a painful and frightening experience.

This injury is caused by exposure to the intense ultraviolet (UV) light generated by the plasma arc. If you’re wondering how to tell if you’ve suffered a flash burn, here are some common signs and symptoms to look out for.

One of the most noticeable symptoms of flash burn is a feeling of sand or grit in your eyes. This sensation is often accompanied by redness, swelling, and excessive tearing.

The eyes may become so swollen that they’re forced shut, causing discomfort and difficulty seeing. Additionally, you may experience sensitivity to light, headaches, and a feeling of pressure behind the eyes.

The skin around your eyes may also become red and swollen, and blisters may form. If you suspect that you’ve experienced a flash burn, it’s essential to seek medical attention immediately.

While flash burns are usually not serious injuries, they can lead to complications if left untreated. Your doctor will likely prescribe eye drops and pain medication to help alleviate your symptoms.

Preventing a flash burn is always better than dealing with its aftermath. To minimize the risk of injury, wear appropriate personal protective equipment (PPE) like safety glasses or welding helmets with UV protection.

Proper ventilation of your work area is also important, as well as taking regular breaks to rest your eyes. In conclusion, while flash burns from plasma cutters can be painful and potentially serious, you can take steps to prevent them from occurring.

Safety Precautions to Avoid Getting Flash Burn from Plasma Cutter

Flash burn is a painful and potentially dangerous condition that can occur when using a plasma cutter.

It’s important to take safety precautions to prevent this injury from happening. One of the primary safety measures to prevent flash burn is to wear appropriate personal protective equipment (PPE).

This includes welding helmets or face shields with shade lenses that can protect your eyes from the UV radiation emitted by the plasma cutter’s arc. Don’t forget to wear protective clothing such as flame-resistant jackets, gloves, and boots to prevent flash burn caused by hot metal spatter or slag.

In addition to PPE, it’s recommended to wear earplugs or earmuffs to protect your hearing from the loud noise generated by the plasma cutter. Taking care of your ears is essential to avoid any hearing damage that could occur while using a plasma cutter.

Proper ventilation is also necessary when using a plasma cutter. Plasma cutting produces fumes and smoke that can be hazardous if inhaled.

Ensure that the workspace is well-ventilated and use respiratory protection if necessary. Before starting the plasma cutting process, always inspect the equipment thoroughly.

Check for damaged cables or connections that could cause electrical malfunction or arc flashback. Additionally, make sure that the workpiece is securely clamped and grounded to prevent electrical shock.

Lastly, having proper training and knowledge of how to use a plasma cutter safely is critical. Understanding how the equipment works and its potential hazards can help prevent accidents and injuries.

Treatment for Flash Burn

Flash burns caused by plasma cutters can be painful and uncomfortable, but with proper treatment, you can promote healing and alleviate the pain.

It is important to remember that even though flash burns are considered minor injuries, they still require adequate treatment. The first step in treating a flash burn is to flush the affected area with cool running water for at least 10-15 minutes.

This is important because it helps to remove any remaining heat from the skin and reduce inflammation. Think of it as extinguishing a fire on your skin.

After flushing the area, gently pat it dry with a clean towel or cloth. To protect the burned skin from further damage and prevent infection, apply a sterile, non-adhesive dressing.

Adhesive bandages should be avoided as they can further irritate the skin. Over-the-counter pain relievers such as acetaminophen or ibuprofen can also help manage the pain associated with flash burns.

Always follow the recommended dosages on the label and avoid using aspirin as it can increase the risk of bleeding. In more severe cases where the flash burn covers a large surface area or is particularly painful, seek medical attention immediately.

Prescription medication or ointments may be necessary to promote healing and prevent infection. It is important to remember that prevention is key when it comes to avoiding flash burns caused by plasma cutters.

Always wear appropriate protective gear such as gloves, eye protection, and a welding helmet when using a plasma cutter. Follow proper safety procedures and use your plasma cutter in a well-ventilated area.

Conclusion

In conclusion, plasma cutters are powerful tools that offer precision cuts on various materials.

However, they come with potential hazards if proper precautions aren’t taken, and one of the most significant risks is flash burn. Flash burn is a painful condition caused by exposure to intense ultraviolet (UV) radiation emitted during welding or plasma cutting operations.

Symptoms include redness, pain, and sensitivity to light. In severe cases, it can even result in a loss of vision or color perception.

To avoid flash burns from plasma cutters, it’s crucial to wear appropriate personal protective equipment (PPE). Welding helmets or face shields with shade lenses protect your eyes from UV radiation.

Flame-resistant jackets, gloves, and boots prevent flash burn caused by hot metal spatter or slag. Proper ventilation of your work area minimizes exposure to harmful fumes and gases.

If you do experience a flash burn from a plasma cutter, seek medical attention immediately.

Treatment involves flushing the affected area with cool water for at least 10-15 minutes and applying a sterile dressing to protect the burned skin from further damage.