Are you tired of the hassle and expense of welding or taking your broken metal to a professional for repair?

We feel your pain. But what if we told you that there’s a simple way to fix broken metal without welding?

Yes, really. With just a little bit of knowledge and a few basic tools, you can save yourself time and money by repairing broken metal on your own.

The best part is that it’s not as complicated as it may seem. You don’t need to be a rocket scientist to do this.

All you need is some patience, some basic tools, and an understanding of how to work with metal. In this post, we’ll guide you through the steps you need to take in order to get your broken metal back in working order.

We’ll show you how to identify the type of metal you’re working with, how to prepare the surface for repair, and the tools and techniques you can use to fix your broken metal. And guess what?

You don’t need any fancy equipment or special training – just follow our lead. So sit back and relax because we’re about to show you How To Fix Broken Metal Without Welding.

Advantages of Fixing Broken Metal Without Welding

Contents

If you’re in need of a metal repair, welding may have been the traditional solution, but there are now alternative methods that are just as effective and more convenient.

In this post, we’ll explore the advantages of fixing broken metal without welding. Firstly, fixing broken metal without welding is cost-effective.

Compared to welding, which can be an expensive process that requires specialized equipment and skills, non-welding methods only require a few basic materials and tools. This makes it a more affordable option for those on a tight budget.

Secondly, fixing broken metal without welding is safer than welding. Welding can pose hazards such as burns and toxic fumes, especially if you are inexperienced or lack proper safety equipment.

By choosing non-welding methods, you can reduce these risks and ensure that your repair process is safe and secure. Thirdly, fixing broken metal without welding is time-saving.

Welding can be a time-consuming process that requires significant preparation time and equipment setup. On the other hand, non-welding methods require less preparation time or equipment setup, which makes them a quicker solution for fixing broken metal.

Fourthly, fixing broken metal without welding is incredibly versatile. This method enables you to repair a wide range of materials, including aluminum, cast iron, steel, and brass.

Additionally, non-welding methods allow for repairs in hard-to-reach areas that would be difficult to access with a welding torch. Lastly, fixing broken metal without welding eliminates distortion.

One of the biggest challenges of welding is that it can cause distortion in the metal being repaired due to heat input. Non-welding methods eliminate this issue as there is no heat applied during the repair process.

This means that you can preserve the original shape and integrity of your metal piece. In conclusion, non-welding methods offer several advantages for fixing broken metal.

Whether you’re repairing a piece of machinery or restoring an antique car, non-welding methods can be the perfect solution.

Using Adhesives to Repair Broken Metal

Not only is it a safer option, but it also allows you to repair a wide range of materials without compromising their original shape and integrity. But what makes using adhesives such an effective method for repairing broken metal?

Well, it’s important to choose the right adhesive for the job. The adhesive needs to be strong enough to withstand the forces acting on the bond while being resistant to heat, water, and chemicals.

Epoxy adhesives are the most commonly used type of adhesive for metal repairs. They’re easy to apply, have a high strength-to-weight ratio, and can be used on various surfaces.

Alternatively, Cyanoacrylate adhesives, also known as super glue, are perfect for repairing small metal parts. They’re easy to use, set quickly, and can bond different types of materials.

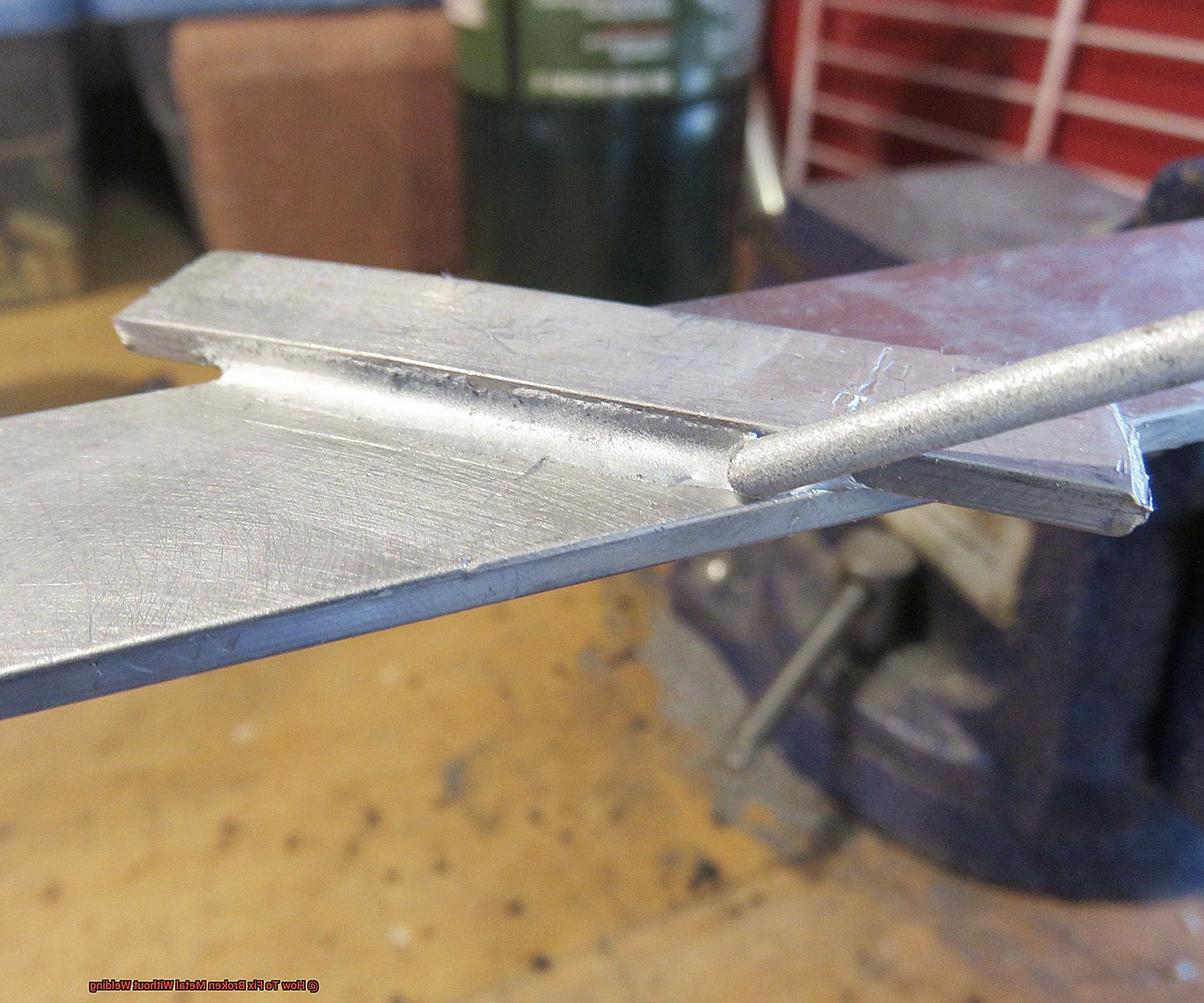

Once you’ve chosen your adhesive, it’s time to prepare the surface. It’s crucial to clean the surface thoroughly to remove any dirt, rust or grease.

Sanding or grinding the surface can help create a good bonding surface. After cleaning, apply the adhesive according to the manufacturer’s instructions.

Some adhesives may require mixing before application. After applying the adhesive, it’s important to clamp or hold the broken parts together until the adhesive sets.

The curing time depends on the type of adhesive used and can range from a few minutes to several hours. Once the adhesive has cured, any excess adhesive can be removed by sanding or scraping.

In conclusion, using adhesives is an effective way to repair broken metal without welding. To ensure success with this method, be sure to choose the right type of adhesive and follow the manufacturer’s instructions closely.

Bolted Joints for Repairs

Bolted joints might just be the solution you need.

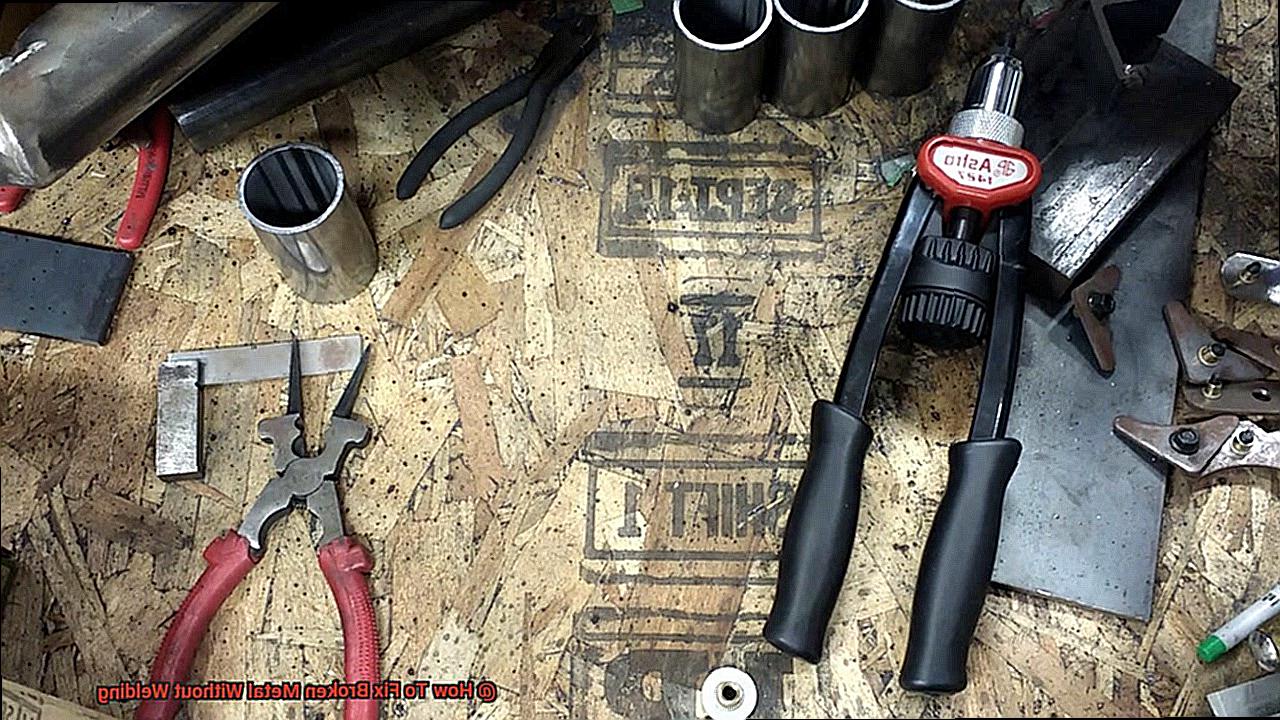

This repair technique involves using bolts and nuts to hold two pieces of metal together, without requiring any welding. To use bolted joints for repairs, you’ll need a few essential tools, including a drill, bolts, nuts, and a torque wrench.

Start by drilling aligned holes in both pieces of metal at the location of the joint. Then, pass the bolts through each hole and secure them with the nuts.

Tighten the nuts by hand until they’re snug, and finally use a torque wrench to tighten them to the appropriate torque specification. Bolted joints are particularly useful when welding is not feasible or undesirable.

For instance, if the metal being repaired is thin or has an unusual shape, welding may not be a viable option. Plus, bolted joints can be easily disassembled if necessary, making them an excellent choice for temporary repairs or situations where future access may be required.

However, it’s important to keep in mind that bolted joints may not be as strong as welded joints. If your repair is in a high-stress area or will be subject to significant vibration or movement, welding may be a better alternative.

Additionally, it’s essential to ensure that the bolts and nuts used in the repair are of high quality and correctly sized for the application. In conclusion, bolted joints are a versatile and cost-effective way to repair broken metal without welding.

Riveting to Connect Two Pieces of Metal

Maybe the metal was too thin or delicate, or perhaps you didn’t have access to a welder.

Whatever the reason may be, there is an alternative that’s often overlooked: riveting. Rivets are metal fasteners that create a permanent connection between two pieces of metal.

It’s easy to install and provides a strong, durable connection that can withstand heavy loads and vibrations. Additionally, riveting can be more cost-effective compared to welding.

To use rivets to connect two pieces of metal, you will require some tools such as a drill, a rivet gun, and some rivets. Start by drilling holes in both pieces of metal where the connection will be made.

The size of the holes will vary depending on the size of the rivets being used. Next, insert the rivets into the holes from one side of the metal and place the rivet gun on the other side.

Firmly press the rivet gun to push the rivet through the hole and flatten it against the metal using a firm pressure. Repeat this process for each hole until all of the rivets have been installed.

It’s crucial to note that while riveting is an excellent option for fixing broken metal, it may not be suitable for all types of metal or applications. For instance, if the broken metal is thin or has a lot of movement, riveting may not be strong enough to create a permanent connection.

Overall, if you need to connect two pieces of metal without welding and want a strong and reliable connection, riveting is undoubtedly worth considering.

Metal Stitching as an Alternative to Welding

It involves drilling holes into the damaged area and using threaded pins or rods to stitch it back together in a specific pattern.

This creates a strong bond that can withstand heavy loads and vibrations. The pins or rods are made of high-strength materials like steel or titanium, ensuring a long-lasting repair.

One of the key advantages of metal stitching is its versatility. It can be used to fix various metals, including cast iron, aluminum, and steel, without compromising their structural integrity.

Unlike welding, metal stitching doesn’t require any heat or electricity, making it a safer option for repairs. But that’s not all – metal stitching is also incredibly simple and efficient.

It requires minimal equipment and can be done quickly, making it ideal for emergency repairs. Whether you need to fix a cracked engine block or repair a damaged industrial machine, metal stitching can get the job done.

Perhaps the most compelling benefit of metal stitching is its ability to distribute load evenly across the surface, making it even stronger than before.

Welding can often weaken surrounding areas due to heat generation during the process, but with metal stitching, you can rest assured that your repair will be solid and long-lasting.

ncTYiKJveEM” >

The Pros and Cons of Each Method

There are several methods available to make your repair quick and efficient.

However, it’s important to consider the pros and cons of each method before choosing the right one for your needs. Let’s take a closer look at the most common methods for fixing broken metal without welding:

Adhesives

Pros

Adhesives are a popular choice as they are easy to apply and can be used on a variety of metals.

They create a strong bond and are ideal for repairing small cracks or breaks.

Cons

Adhesives may not be suitable for certain types of metals or if the broken piece is under a lot of stress.

Proper surface preparation is also required for optimal adhesion.

Brazing

Pros

Brazing is an effective method for repairing small cracks or breaks. It can be used on a variety of metals and creates a strong bond that can withstand high temperatures.

Cons

Brazing requires some skill and knowledge to perform correctly. It also requires specialized equipment and can be time-consuming.

Soldering

Pros

Soldering is similar to brazing but is ideal for repairing small breaks or cracks in non-stress areas.

It is also easy to use and can be done with basic equipment. Cons: Soldering may not be suitable for larger breaks or cracks.

It also creates a weaker bond than brazing and may not be able to withstand high temperatures.

Mechanical fasteners

Pros

Mechanical fasteners such as bolts, screws, and rivets are easy to use and create a strong bond. They can also be used on a variety of metals.

Cons

Mechanical fasteners may not be suitable for certain types of metals or if the broken piece is under a lot of stress. Proper installation techniques are also required for optimal strength.

So, each method for fixing broken metal without welding has its own set of pros and cons that should be carefully considered before making a decision. Adhesives are a quick fix but may not be suitable for all situations.

Brazing and soldering require more skill and knowledge but create stronger bonds. Mechanical fasteners are easy to use but may not be suitable for all types of metals or situations.

Also Read: How to repair wrought iron without welding? – The Welding Guru

Conclusion

In conclusion, fixing broken metal without welding is a cost-effective, versatile, and time-saving alternative that can save you from the hassle and expense of welding or taking your broken metal to a professional for repair.

Adhesives are an excellent option for repairing small cracks or breaks in various metals. They offer a quick fix that is easy to apply and can be used on different types of metals.

Brazing and soldering require more skill and knowledge but create stronger bonds that can withstand high temperatures. These methods are ideal for repairing more significant damages in metals.

Mechanical fasteners such as bolts, screws, and rivets are also easy to use and create a robust bond that can be used on various metals. However, if you’re looking for a versatile, safe, efficient method that maintains structural integrity while offering strength and durability, then metal stitching is the way to go.

It’s quickly becoming popular as an alternative to welding because it offers a long-lasting solution without any distortion. Before choosing the right method for your needs, analyze the specific requirements of your repair carefully.

This will ensure you choose the most effective solution for a long-lasting result. With just a little bit of knowledge and some basic tools at your disposal, you can embark on some serious DIY action.