Are you searching for the answers to the question “Can you mig weld brass to steel?”

You will find very knowledgeable people and sundry of pieces of information on this topic. Perhaps you start with the prospect of welding brass to steel.

Brass is one of the most malleable metals you could possibly use in your metal welding projects. Brass is an alloy or mixture made up of copper and zinc.

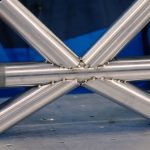

Steel is a sturdy metallic material that’s often used for construction purposes. When brass is joined to steel through welding, the resulting product is known as brass steel.

Can You Mig Weld Brass To Steel?

Contents

To be completely honest, you would be better off making the brass hoop out of aluminum or copper.

You may, however, use the brazing process, which bonds the two together.

Additionally, you’ll need to have the rod gapped (this is where the rod will be elongated) before welding.

If you’re wondering if you can weld brass to steel, the answer is no. The joining of brass to steel would require brazing.

Why you can’t weld the brass to steel?

Welding brass to steel is hard because the melting temperature of the metal is different.

When welding brass to steel, it is important to heat the material to its highest melting point before attempting to weld the two together.

Professionals advise that you heat the brass to melting temperature before you attempt to weld it.

To connect the brass to steel, you need to heat the brass to its highest melting point. If the brass steel becomes too hot, it will melt together.

The major reason why you can’t weld brass to steel is that the temperature of the two materials does not match.

If the two materials do match, you run the risk of melting the brass.

Perhaps you can see why a professional welder would want to use a torch instead of a simple soldering iron.

How you can weld the brass to steel?

You have gathered some vital information about brass and steel and how to weld them together.

As a result, you know that TIG brazing is not a suitable method for welding brass. Instead, you are best off choosing plasma arc welding, flux cored arc welding, or induction welding.

As a result, you should be familiar with the material you’re using before you begin this welding endeavor.

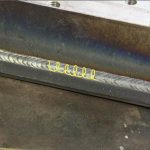

Different types of welding can completely change the appearance of the steel, so you’ll need to put some thought into this decision.

Welding is not an advisable method for strong connection welding on brass to steel because excessive heat could damage the metals, and this could affect the integrity of the joint.

However, TIG welding is most commonly used with brass and steel welding.

Many people feel that TIG brazing is the most expensive option of the three, but it is also the most secure.

However, brazing is a time-consuming process, so TIG brazing becomes only an option when you’re in a hurry.

Before you weld brass to steel, you’ll need to have the right tools for the job.

Since brazing is a DIY job, you can usually make the necessary parts yourself.

How to Mig Weld the Brass?

After you’ve mastered the fundamentals of welding brass, it’s the right time to learn the specific procedures.

When you are welding brass, there are a few points you must remember. First, the aluminum alloys used for most parts need to be pre-tempered.

This is usually done by heating the material to a liquid state. The liquid metal is then injected into pressurized molds to create the desired shape.

The liquid metal is then allowed to cool and solidify. When it comes to the processes used for welding brass, there are quite a few tools you can use to get the job done effectively.

For different projects, you may find that you need to change the material you’re working with or the type of brazing alloy you’ll be using.

One key element when using brazing alloys with brass is to prevent overheating.

If your weld heats too quickly, chances are that the alloy will turn from liquid to vapor before you’ve actually completed your weld.

As a result, your weld won’t be as strong as it could be, and you may have trouble doing it again in the future.

Over the years, we have worked with many individuals that unintentionally weld brass, and it usually ends up harming their project. In this project, we will cover how to properly weld the brass.

You’ll see that the process is very simple. The initial step is to heat the brass.

We’re going to use a propane torch on this. Once you heat up the brass, you can place it onto the TIG welding machine.

This will allow you to make a nice, clean, smooth, and hidden weld.

Combine the flux and the water

First, you’ll need to combine the flux and the water.

Next, use a plumbing brush to apply the weld flux to the pipe or fitting to be welded. The filler rod will mix with the flux and begin to create paste.

It is important to apply the flux slowly, using the plumbing brush.

After applying the flux, you will need to use a ground clamp to hold the object that you are welding.

Now you can start welding. To produce a suitable paste, you need a bucket, a funnel, flux powder, and some water.

This paste is used to weld brass.

After completing this step, apply flux to the surface of the metal you’re welding; this will ensure that it cleans up easily after welding.

When using metal for welding, you need to make sure that the solder does not contaminate the entire workpiece.

Make use of a brazing welding flux

This is a particular welding flux that, when properly utilized, can braze welding brass for you. The process is, actually, fairly straightforward.

After you’ve completed the previous step, you heat up the flux and dissolve the flux powder in the molten metal.

you will also want to incorporate your flux into the weld pool. Using a flux is necessary to ensure that the filler metal doesn’t stick in the weld pool.

This might become yet another service offered by your welding business.

This particular process is brazing, and it requires a large amount of heat and pressure. The heat is necessary because the flux is meant to be melted.

The heat is then forced inside the walls of the brass to form a strong bond.

Reduce the flow of acetylene

When it comes to ensuring that it will perform well on the piece you are welding, ensure that the flame is penetrating the piece.

If your welding rod does not penetrate enough to make a hole, you may have to use a thicker rod.

This will help the flow of acetylene in the torch, and allow you to weld the piece at a better pace.

The acetylene flow rate and temperature of the weld flame depend on the gas pressure in the welding torch. The hotter the flame, the higher the flow rate.

Use braze welding fillers

You need to use filler material that is free from cracks or chips. The filler material should be free from defects.

You should always use braze welding filler that is intended for your type of metal.

Make sure you pay attention to the thickness of the filler, because the thickness of the filler’s coat will determine whether it is able to fill the entirety of the groove.

Make sure the braze welding filler you use is clear of debris. The filler should be free of impurities, such as dirt and sand.

Use a welding tip

In the last phase, you’ll need to use a welding tip to weld the brass.

The tip used for welding brass is made to achieve different effects depending on the type of brass that you’re welding.

For example, if you’re welding brass rods, you’ll use a small tip to weld the rods because it will heat the rods and make them more malleable.

However, if you’re welding a brass pipe, you’ll use a wide tip in order to weld the pipe.

This is the ultimate technique to follow if you do not want to melt the brass you’re working with.

Generally, you can weld metal with a welding tip without a problem.

However, it’s a good idea to have a spare tip on hand just in case you run into one that doesn’t work.